The industry has had to adapt to much tighter welding specifications and a whole new set of regulatory standards that were finalized after 2020. What I remember as a simple equipment rental has turned into something far more involved. You need certifications now and have to follow so much documentation protocol. These machines need to integrate with other systems in ways that most rental agreements just don’t spell out at first when you sign on the dotted line.

The pricing structure varies for beveling machines. Many companies figure that if they’re going to use the equipment for less than 200 or so hours a year, then rental is the way to go. That calculation works great on paper, but falls apart pretty fast in the real world. Your operators need time to learn the equipment, and that’s productive time that you’re losing. Then there’s the downtime when something goes wrong. And here’s what gets expensive – most rental machines don’t have the documentation features that the pipeline integrity management systems require these days.

Rental shops will show you the machines with specifications for pipe diameters and wall thicknesses. Those numbers are helpful reference points. But they don’t tell you everything you need to know about performance with different materials. Some bevelers are rated for 2-inch wall thickness and will cut through carbon steel like butter. Give that same machine some high-alloy material at the same thickness, though, and suddenly it’s a different story.

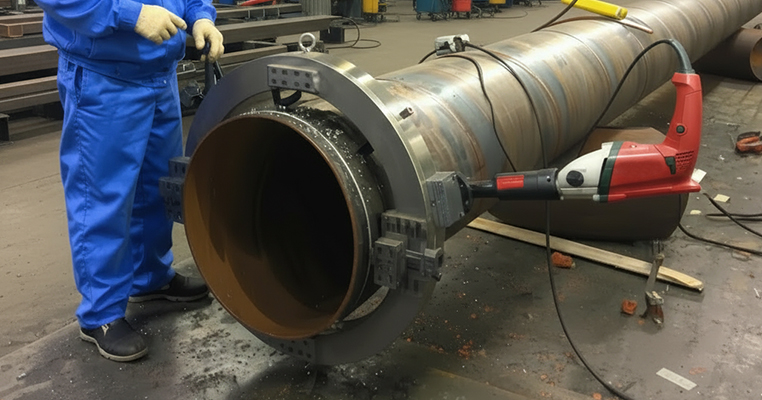

Let’s go over everything you need to know about renting pipe beveling equipment!

Equipment Types That Match Your Pipes

Pipe beveling equipment rental can be hard to figure out if you don’t know what you need for your specific project. The most essential part is to get a machine that matches your pipe specifications just right. The problem is that a lot of rental places will try to rent you whatever they have sitting in their warehouse instead of what actually makes sense for your job – and that’s usually when everything starts to go wrong.

But orbital bevelers are great machines for pipes that measure anywhere from 2 to 12 inches in diameter. When you start working with pipes over 8 inches, though, you should look at large bore machines instead. These bigger units work with pipes all the way to 48 inches in diameter. You’ll see that there’s some overlap in that 8 to 12 inch range, and that’s because wall thickness is actually just as essential as diameter when you’re picking equipment.

Even if a machine says it works with a 2-inch wall thickness on the spec sheet, it might not perform well with every type of material you throw at it. Carbon steel behaves one way as you cut it. But stainless steel and other alloys will behave differently. The rental company’s spec sheet probably won’t tell you about these material limitations either. The performance also changes quite a bit based on how hard the material is and what heat treatment it’s had.

Different manufacturers build equipment in their own ways, too. Kramer, GBC and Reed all make quality machines. But each brand has its own strengths. Some of them are great at maintaining a steady bevel angle throughout the cut. Others are built to be more portable or to work faster. These technical differences matter a lot when you’re racing against a project deadline and every hour counts.

The wrong equipment choice creates a series of expensive problems. Your operators will waste hours just trying to get the machine to cooperate. The bevels that they eventually produce won’t be steady enough to pass inspection. At that point, you’re stuck renting a different machine and doing the work over again. Between the extra rental fees and that wasted labor, the costs spiral out of control fast.

Those savings you expected from renting the cheaper unit are gone. Your planned schedule falls apart as delays pile up. Your customer starts asking very pointed questions about when you’re going to finish their project.

The Right Rental Duration for Your Project

Most contractors immediately pull out their calculators when they hear rental rates that range anywhere from $150 to $800 per day. The math looks pretty simple on paper. Any equipment that gets a few hundred hours of use each year probably makes more sense to buy than to rent.

Your actual work schedule changes the calculation. The total hours alone don’t tell you everything. Maybe you need a beveler for three different projects that are spread throughout the year, and each project runs about two weeks. Six weeks of steady use isn’t enough to justify buying one when the equipment sits in storage for 46 weeks every year, as it slowly loses value.

Weekly rentals usually have a 20% – 30% discount compared to day-to-day rates. Monthly deals can save you even more money, especially if you’re willing to negotiate. Rental shops want your business if you have a project that runs two months or longer. Most of them will definitely work with you on the price.

The true savings actually show up in unexpected places. Annual calibration costs disappear, and you never have to worry about storage space for large equipment. The technology in this industry also moves very fast. A beveler that seems state-of-the-art today could be outdated in three years. At the same time, rental shops are always updating their inventory with the latest models.

Multiple projects that are scheduled in the same quarter could be the perfect opportunity for a blanket rental agreement. These agreements let you lock in better rates and guarantee equipment availability right when you need it. Research shows that usage typically ends up about 40% lower once contractors actually buy them.

Check and Document Your Rental Equipment

Rental equipment needs careful inspection before you take it off the lot. The cutting head deserves your attention first since any wear there will throw off every bevel you cut. A damaged cutting head might run fine for the first few cuts.

The drive motor is another important component that needs careful evaluation. It needs to give you steady torque through its entire rotation cycle without any problems. Test it under actual load whenever possible and listen for any weird noises or stutters in the rotation. These motors get beaten up pretty badly on job sites, and rental shops miss the problems all the time when they rush equipment back out the door.

Electronic readouts are only helpful when they’re actually accurate. Verify the display readings against a reference angle that you trust and watch to see if the numbers stay put or drift around. Older units tend to lose their calibration after they heat up. You don’t want to cut fifty pieces at the wrong angle because you trusted a faulty display.

Documentation protects you from bogus damage claims later. Take photos of everything before you sign that rental agreement. Every scratch on the housing needs to be in your photos, and the clamping mechanisms deserve extra attention because they take the most abuse. Rental shops have a reputation for charging the last customer for pre-existing damage. Make them acknowledge every ding and scratch in writing on the rental form.

Maintenance history tells you more than any visual inspection ever could. Most shops’ automated beveling equipment is down for repairs about 5% to 10% of the time, and that’s with regular maintenance programs. A rental company that shares its logs is doing you a favor. The problem is chronic if there are repeated repairs on the same component, and it will probably resurface during your rental period. Walk away and request a different machine.

New Safety Rules for Equipment Operators

Most rental places have updated their policies over the last few years, and now each one makes you sit through a 4 – to 8-hour training program. The whole industry also changed when new safety regulations rolled out in 2020. Veterans with decades of experience on pipe beveling machines still have to get certified on every model that they want to rent.

This requirement might sound like overkill for experienced operators. But each manufacturer has their own way to design controls and interfaces. A machine built by one company is going to work differently from another company’s version when the machines do the exact same job. The newer models with computerized interfaces can be especially confusing for operators who are used to the older mechanical controls. An operator could be great at beveling pipe. But it still takes a few hours just to learn where all the buttons are and what each setting actually does on a new machine.

The legal implications are where this starts to matter. Using equipment without the right certification means your insurance company usually doesn’t cover the damages when something goes wrong. OSHA fines for certification violations usually hit tens of thousands of dollars. A 4-hour training course starts to sound pretty worth it compared to those kinds of consequences.

Project timelines need some adjustment as well. Most operators find that their productivity drops by about 20% to 30% during the first week with unfamiliar equipment. It’s also a natural part of the learning curve as the operators learn each machine’s particular features.

Some project managers want to skip the certification process and jump right into production. This tends to cause bigger problems down the line when accidents happen or the bevels don’t meet the specifications because the operators didn’t know the right settings for that particular machine.

Who Handles the Daily Maintenance Tasks

Automated pipe beveling equipment rentals have a whole bunch of maintenance responsibilities, and you need to know which ones are yours before you sign any paperwork. Most rental agreements are pretty simple about the basics and expect you to take care of all the day-to-day tasks. You’ll be responsible for cleaning the machine after each use, and you need to make sure all the moving parts stay well lubricated, too. The cutting heads are another expense that lands in your lap because you have to replace them yourself when they start to wear down. The benefit is that rental places usually take care of the big mechanical problems and big repairs as long as those problems happen during normal operation.

The contract language around maintenance can be a minefield, though. There’s usually a big distinction between what they call “normal wear” and what they classify as “operator damage” – and this distinction can cost you thousands of dollars if you’re not careful. A hydraulic pump that fails after years of normal use is almost certainly their problem to fix. But if that same pump fails because your crew forgot to check the hydraulic fluid levels, you’re going to be paying for that repair out of your own pocket, and those invoices aren’t small.

Equipment failures on time-sensitive projects can be brutal. A single morning without your beveling machine can cascade into a three-day delay for your entire automated welding schedule. Everything gets pushed back, and the deadlines start slipping, and suddenly, your whole project timeline is in jeopardy. A rental company that has legitimate four-hour response times and round-the-clock support is going to save your bacon when your equipment decides to quit working at two in the morning. Machinery tends to break down at the worst possible moments.

You also need specific information about spare parts inventory before you commit to anything. The rental places will usually supply all the big parts and expensive replacement parts. But they expect you to keep your own stock of everyday consumables. Cutting inserts, hydraulic filters, and other wear items are usually your responsibility. Get a list of everything that you’re expected to have on hand and get it in writing before you sign that rental agreement.

Smart Features That Prevent Costly Mistakes

Paper logbooks and manual measurements used to be the standard for pipeline projects, and that was fine for a long time. However, most contractors need equipment that automatically tracks all cuts and saves all that data without any manual input. A modern beveling machine will connect right to your welding management software and create its own paper trail as it runs.

All this technology might seem excessive at first. When an inspector shows up three weeks later and wants the records on one particular bevel, though, that electronic record definitely pays off. The machine captures the exact angle and timestamp for every cut that it makes. There’s no room for debate about whether a bevel actually meets the spec because all the data is already stored in the system.

It’ll push the rental price up a bit. Having to re-cut a bad bevel means that your entire crew stands around doing nothing as somebody fixes the mistake. The whole schedule gets pushed back, and everyone starts to become frustrated. Automatic angle verification will catch most of these problems way before they have a chance to turn into expensive delays.

Operators who’ve been doing this for years might grumble about touchscreens and menus when they first see them. Equipment that has interfaces like what your crew already knows from other machines will make the transition much easier. Half a day just to learn how to change essential settings is a waste of everyone’s time. Most newer systems actually work similarly to the apps on your phone and also help speed the process.

The ability to troubleshoot remotely can save thousands of dollars on a single project. Something stops working right, and the rental company can usually diagnose and fix the problem through the cloud connection. A 3-hour wait for a technician to drive out to your site turns into a 10-minute phone call instead.

Where The Pros Get Their Welding Rentals

The pipe beveling industry has gone through some pretty big changes, and I’ve been around long enough to watch plenty of teams as they figure it out through trial and error. The rental process for these machines is simple on paper. Experienced crews run into unexpected costs all the time, and it’s usually because they didn’t read through all the documentation from start to finish, or they overestimated what their operators actually knew how to work with.

After years in this business, a pattern emerges with the teams that always get great results. They put in the effort to get familiar with the equipment that they’re about to rent, build contingencies into their plans and make sure that each person on the crew knows what they’re responsible for before the work begins. The successful teams also know that it’s worth it to pay a little extra at the beginning for better features or more thorough documentation systems. Those early costs will usually pay off if you look at the entire project timeline.

This brings up an important consideration for your upcoming projects. At Red-D-Arc, we’ve spent years working directly with welders and fabrication teams to solve these exact problems, and we know how much it matters to have reliable equipment available right when you need it. Our rental catalog covers everything that you might ever need, from standard welding machines all the way to advanced pipe beveling systems. We also carry all the positioning equipment and safety gear that you’ll need to finish the job safely. We designed our entire rental program based on feedback from professionals who work with this equipment every day. We have flexible rental terms, carefully maintained machines and technical support whenever you run into problems.

You can check us out at red-d-arc.com to look through our full inventory and learn how our rental programs can help with whatever challenges come up on your next project!

Sources & references

- 49 CFR Part 192: Safety of Gas Transmission Pipelines – The U.S. federal regulation has updated requirements post-2020 (known as the Gas Mega Rule) that significantly increase the need for lifetime documentation of material properties and construction quality.

- CER Safety Advisory SA 2020-01 – The Canada Energy Regulator (CER) issued this advisory in February 2020 concerning girth weld area strain-induced failures on high-strength pipe, demanding higher precision in weld prep and integrity management.

Leave a Reply