Recent Articles

Stay updated with our latest insights in welding, featuring expert tips, company news, product discussions and more.

Filter

Three-Phase vs Single-Phase Power for Orbital Welding

Choosing between single-phase and three-phase power is a critical decision that impacts everything from arc stability and penetration depth to long-term electrical efficiency. While modern inverter technology…

Capital Conservation: Why Leading Fabricators are Moving to “Equipment-as-a-Service”

Modern metal fabrication leaders are moving away from traditional ownership in favor of agile “equipment-as-a-service” models to preserve capital and eliminate maintenance burdens. By leveraging Red-D-Arc’s rental…

How Cold Weather Affects Welding Equipment Performance

When temperatures drop, welding equipment faces unique physical stressors ranging from reduced battery capacity and stiffened drive liners to the serious risk of internal condensation. This guide…

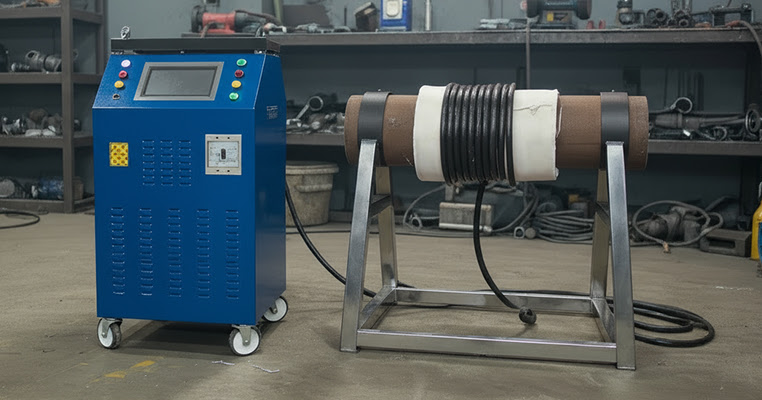

How to Pick the Best PWHT Equipment for the Job

Choosing the right post-weld heat treatment equipment requires balancing material requirements, code compliance, and operational efficiency. This guide breaks down the critical differences between induction and resistance…

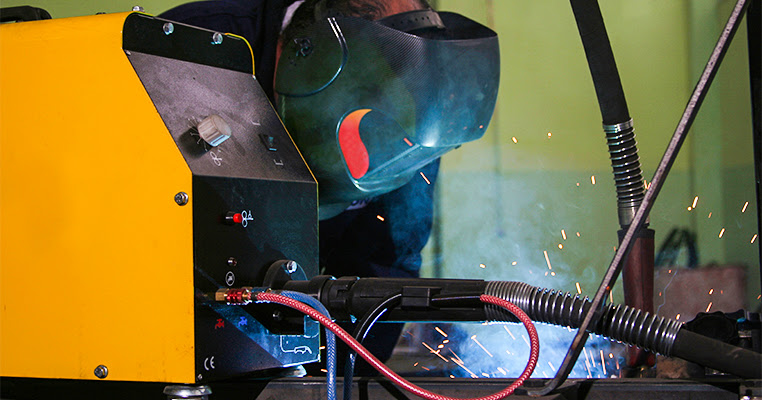

250A vs 350A – Which Welder is Best for Field Work?

Deciding between a 250A vs 350A welder for field work often comes down to the trade-off between the ease of carrying a portable machine and the raw…

Red-D-Arc 70th Anniversary Spotlight: George Zammit

As we celebrate Red-D-Arc’s 70th anniversary, we’re concluding our employee spotlight series with a feature on long-standing team member George Zammit. With more than three decades with…

How to Size Generators for Multi-Welder Job Sites

Choosing the right generator size for multi-welder job sites can save you from wasted fuel, tripped breakers, and expensive delays. This guide explains how duty cycles, diversity…

Red-D-Arc 70th Anniversary Spotlight: Mark Jacklin

Mark Jacklin reflects on his decades-long career at Red-D-Arc, sharing insights into how leadership, collaboration, and operational innovation have shaped the company’s success. From initiatives like implementing…

Case Study: Induction Heating and Support from Red-D-Arc Specialists Help Achieve a Precise Fit

A leading structural steel fabricator partnered with Red-D-Arc to overcome a complex bridge assembly challenge. Using rented Miller® ProHeat™ 35 induction systems and custom heating blankets, the…

Contact Us

Connect with your local Red-D-Arc sales team or our other welding industry experts by using this form.

Copyright © 2026 Red-D-Arc Inc. All rights reserved.