Post-weld heat treatment equipment is the type of purchase that can make or break your entire welding operation. Pick the right setup and you’ll pass every code inspection with no problems at all. Pick the wrong one and you’ll be stuck with failed inspections, blown budgets and project delays for years to come.

The selection process gets tough because what works great for one job could be wrong for another. A furnace designed for heavy, thick-walled pressure vessels might be completely impractical if your primary workload involves heat treating thin-walled chromium-molybdenum piping. The thermal inertia of a large furnace simply isn’t calibrated for the precision and rapid cooling cycles required for smaller, thinner components. Field contractors who need to haul portable units out to the middle of nowhere have a whole different set of problems than the fabrication shops that run furnace cycles all day long in the same place.

Modern induction systems are incredibly efficient because they generate heat directly within the part, whereas traditional resistance setups can lose a significant amount of energy to the surrounding air. In resistance heating, while the electrical conversion is high, you are essentially fighting a battle against thermal lag and heat dissipation through the insulation, which can drive up your utility costs on long soak cycles. Some applications still need those older methods to work correctly.

The cost of ownership is where the situation gets interesting. Companies buy what looks like a great deal on paper – then six months later, they find out that their equipment needs calibration every other week. Or the heating elements burn out. Or worse – the documentation system is so outdated that auditors just shake their heads when they see it. Magnetic pad systems can cut your setup time by more than 50% compared to the old stud gun methods – but your workpieces might not accept magnetic attachment in the first place.

The equipment capabilities need to match up with what you’re actually trying to accomplish with your heat treatment process.

Let’s look at how you can choose the right PWHT equipment for your goals!

Match Your Shop to the Right Equipment

The right PWHT equipment for your shop depends on a few factors. The biggest one is probably the actual work that you do day in and day out. Go ahead and grab a tape measure and document the dimensions of your usual workpieces. Write them all down and track them for a while. A shop that primarily works with small pipe spools is going to need different equipment than one that usually treats massive pressure vessels. Size matters here. But the materials you work with are equally significant.

Carbon steel and chromium-molybdenum alloys need different strategies for heat treatment. Every material has its own exact temperature requirements, and the hold times vary quite a bit, too. Pull up your job records from the last few months and make a list of which materials show up most frequently. What you find might be different from what you expect.

Production volume is another big factor that influences equipment decisions substantially. A shop that only treats 5 pieces a month can get by with simpler equipment. But if you’re running heat treatments every day of the week, you need equipment built for that steady workload. Reliability matters quite a bit when downtime means that you’ll miss deadlines.

The physical reality of your workspace will also dictate much about which equipment actually makes sense. Some shops have plenty of three-phase power available throughout the facility, and others are limited to standard outlets. Floor space and ceiling height create similar constraints. Field service contractors face even harder limitations because they have to transport their equipment to different job sites every week.

Code requirements aren’t optional, and they can change based on your industry and location. Code requirements aren’t optional, and they vary depending on your specific project. While API 570 and NBIC govern inspections and repairs, the primary requirements for PWHT usually stem from ASME Section VIII for pressure vessels or ASME B31.3 for process piping. These codes dictate strict temperature bands and ramp rates that your equipment must be able to hit and document flawlessly to avoid expensive rework.

Veteran technicians will tell you that your assumptions and your actual data are usually two different stories. I see shops that make this mistake constantly. Track your heat treatments meticulously for a few months and document everything. The patterns that emerge might change your equipment purchasing decisions!

The Best Heat Method for Each Job

The heat generation technique is probably the most important factor that determines if your PWHT process is going to work right or not. Every heating method out there has specific applications where it performs best.

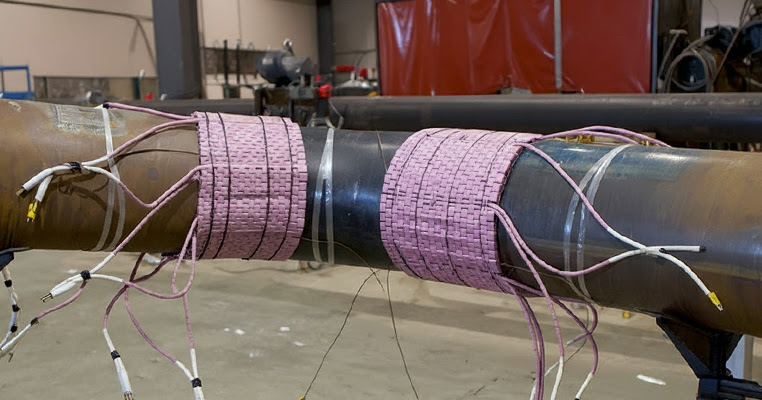

Induction heating uses electromagnetic fields that actually heat the metal from the inside out. It works really well at maintaining uniform temperature zones in cylindrical shapes, especially pipeline girth welds. The electromagnetic fields wrap themselves around the entire pipe and heat everything evenly without any hot spots. Watching experienced operators use it hundreds of times never gets old – it’s still amazing how well it works.

Resistance heating operates differently and relies on ceramic pad heaters or flexible heating elements instead. These can conform to tricky shapes that would be nearly impossible to heat right with other methods. The flexibility is a big help when you have to treat irregular weld joints or equipment with unusual angles that just won’t cooperate otherwise. Fabricators do run into problems with the resistance elements staying attached on vertical surfaces. But once they start working with magnetic holding systems, the whole process gets much more manageable.

Flame heating remains useful when you have to treat massive structures that other methods can’t handle. The electrical methods just aren’t practical on very large steel assemblies or at remote job sites where you don’t have adequate power access. The hard part is manipulating the torch correctly to avoid uneven heating patterns. You need experienced operators who know how to keep steady temperatures across large surface areas.

The material choice is a major factor in determining which heating method is most effective. Induction heating works best on magnetic materials like carbon steel, where the magnetic hysteresis and eddy currents generate heat rapidly. However, non-ferrous materials like aluminum have high thermal conductivity and no magnetic permeability, which makes them much more difficult to heat via induction.

In these cases, or when working with low-conductivity stainless steels, resistance heating is often the superior choice. Resistance methods provide a steady, penetrating heat that prevents ‘hot spots’ and allows for a more controlled soak. This is critical for ensuring the heat reaches the core of the material without overheating the surface, maintaining the specific metallurgical properties required by the job.

Control Systems That Keep Your Temperature Steady

Control systems are necessary for heat treatment processes to work properly. Temperature uniformity is one factor that can make everything fall apart if you don’t get it right. Temperature uniformity is the factor that ensures the entire weldment reaches the desired state without creating new stresses. ASME codes are very specific about the ‘soak’ range; depending on the material and thickness, you may be required to keep the entire heat zone within a narrow window—sometimes as tight as 50°F between your hottest and coldest sensors. Your equipment has to deliver this level of precision consistently, or you risk the integrity of the steel. Your equipment has to deliver this level of accuracy each and every time, or you’re going to have big problems.

Multi-zone controllers are the way to go if you need uniformity on bigger parts. Each zone monitors its own area and adjusts independently when the temperatures start to drift. At the same time, the whole system works together to coordinate the zones. This setup is what prevents those dangerous hot areas that can destroy your material properties. Without proper coordination between zones, you’ll get left with weak areas in your final product.

Thermocouple placement is one area where experience shows. The code might tell you that six sensor points are enough. But experienced technicians will usually install twice that number. Extra data points are like insurance against unexpected failures. The thickest sections of your workpiece need to have thermocouples without question. Any areas where heat tends to escape also need coverage. More data means fewer unexpected issues and better quality control.

Ramp rates need a lot more thought than just cranking up the heat. Thick materials and anything brittle will crack if the temperature rises too fast. Most modern controllers allow different heating rates for each stage of your treatment cycle. This flexibility is great, and you should use it to protect your materials.

Data logging technology has changed over the past few years. The modern systems take all your temperature data and send it wirelessly to cloud storage. An auditor can walk in months after a job, and you’ll have each and every temperature reading ready to show them. This level of documentation is great for liability protection and also proves your work meets the necessary specifications.

Redundant control loops are really worth the investment, even though they’re expensive up front. Single-point failures have ruined tons of batches of materials over the years. The cost of one scrapped batch usually exceeds the price of that backup system anyway.

Fixed and Portable Equipment for Your Projects

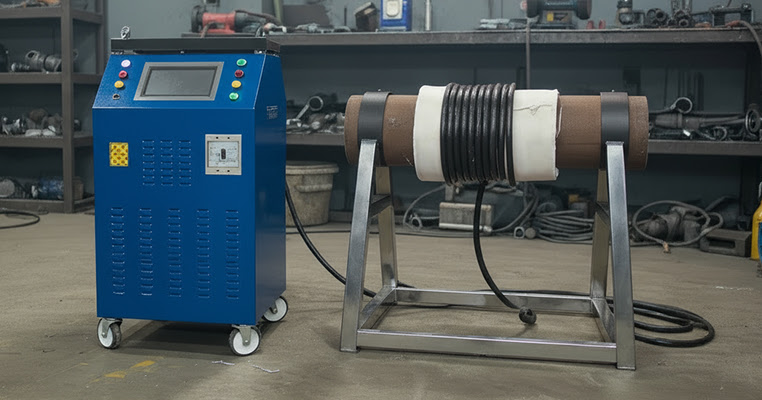

Portable electric heat treatment systems have genuinely changed the landscape for contractors who work on massive refinery vessels or installed pipe systems because you can’t throw a 50-ton vessel on the back of a flatbed and drive it to your shop. These systems deliver the same precise temperature control that you’d get from a fixed furnace, except they travel directly to wherever your work happens to be. The main challenge is that you have to work out your power generation requirements ahead of time, and it takes careful planning before you roll to the job site.

Field work is a different animal, though. Pipeline repairs don’t wait for convenient timing, and they don’t happen in convenient locations with access to three-phase power. Most successful contractors actually own both types of equipment for this reason. Their shop furnaces take care of the predictable production work where efficiency and repeatability matter. Their portable units stay ready for emergency calls, remote installations and those projects where the customer needs everything done on-site without any disruption to their operations. It’s a sensible way that covers all bases.

I’ve watched a few contractors learn this lesson the hard way after years of trying to transport massive weldments back to their shops. Once they added up crane rentals, oversized load permits, pilot cars, road closures and the inevitable insurance claim from transportation damage, the math became pretty obvious. The portable equipment suddenly looked like a smart deal! Insurance carriers have also seen the safety benefits. Electric portable systems carry substantially lower risk profiles than gas-fired alternatives – and that translates directly into better premium rates for contractors who make the switch.

Your best equipment choice depends on the work that keeps your crews busy. Field repairs and retrofit projects make portable systems an obvious investment that pays dividends almost right away. Shop-heavy operations might only break out the portable gear for specific circumstances, and that’s fine too.

Smart Features That Make Your Work Easier

Modern PWHT equipment has definitely evolved way past those old pen-and-paper systems we used to work with. Automatic documentation is a perfect example of what I mean. The system captures and logs all your temperature readings throughout the entire cycle, so you don’t have to stand there with a clipboard anymore. This is especially important if you work in nuclear or aerospace manufacturing, where just one number written down wrong could cause your entire audit to fail. A few fabricators actually calculated their labor hours and found out that their technicians were spending more time on paperwork than they were on the heat treatment process.

The wireless tracking features are another real benefit. Your equipment can send notifications directly to your phone whenever something isn’t right with the treatment cycle. There’s nothing worse than walking in on Monday morning and finding out that your treatment had failed at 2:00 a.m. on Saturday night. These real-time alerts give you the chance to fix problems so you don’t lose an entire weekend’s worth of production.

Most of the newer systems will also integrate well with whatever quality management software you’re already running. You can generate all your certificates and store full job histories without having to type the same information into multiple systems. All that data just flows automatically from your equipment straight through to your final documentation.

The fault detection technology in these units is worth talking about, too. Modern systems can detect when a thermocouple is about to fail well before it dies on you. The software picks up on those early warning patterns and tells you that it’s time for a replacement. This predictive maintenance approach has helped plenty of shops to stay away from ruined treatments and frustrated customers.

All these computerized features become really useful when you start to work with them. You’ll soon see just how much time they save and how they stop problems from happening. The automation takes care of the repetitive tasks that nobody wants to handle, so you can spend your time making sure the heat treatment process runs right.

The Real Cost of Your Equipment

Two pieces of PWHT equipment can have identical price tags and still have wildly different ownership costs. Most buyers only discover this after they’re already deep into their first year of ownership. The equipment featuring advanced thermal management and high-density insulation will save you a fortune in the long run. When you compare modern systems to older, poorly maintained resistance setups, the difference in energy consumption is staggering. By minimizing heat loss to the shop floor, you aren’t just saving on the power bill; you’re also creating a safer, more comfortable environment for your technicians. We’re talking about cutting your energy bills right in half when you’re running these machines for 8 hours every day. Those savings add up fast, and they never stop adding up.

The sticker price on that machine is really just the entry fee for what you’re about to spend over the next few years. Your certifications won’t stay valid without regular calibration services, and those aren’t cheap. Thermocouples are consumables that burn out and need to be replaced every couple of months at a minimum. Heating elements eventually fail, too, and the timeline changes dramatically between manufacturers. The cheap equipment tends to need new elements almost every year. The well-built machines can go 3 or 4 years before they need to be swapped out.

I watched a contractor lose a big pipeline contract after his equipment broke down three times in 14 days. The client ran out of patience with the delays and brought in a different company to finish the project. Once your reputation gets damaged from something like that, you have an uphill battle to win back trust that some businesses never recover from.

Equipment that’s hard to use brings hidden expenses. Your technicians are expensive, and if they waste half of their workday trying to understand error messages or work through confusing menus, that’s your productivity down the drain. Interface simplicity saves serious money. Calculate how much those wasted hours cost you every month, and it becomes a major consideration.

The physical size of your equipment also changes your business operations. A machine that’s too small turns into a choke point that limits the number of jobs you can accept. But if you go overboard and buy something massive, you get stuck paying for the power and capability that sits idle.

Where The Pros Get Their Welding Rentals

Equipment selection is all about balance – you need to find what actually works for your technical requirements and your everyday operations. Each shop has its own specific combination of workpiece dimensions, production timelines and quality requirements that shape which equipment makes the most sense. The perfect setup for one company could be wrong for another company, even when they’re in the same industry, making similar products.

The technology available in heat treatment equipment gets better each year – your existing setup might become outdated quickly since the market keeps advancing. It makes sense to periodically review what’s available on the market and compare it to what you’re currently running in your shop. The most successful shops I work with are the ones that review their equipment performance against newer options on the market every once in a while. Those records become very helpful when the time comes to upgrade or replace equipment.

When shops look at their workload data, they usually discover that a few smaller units would serve them much better than the largest and most expensive system on the market. Others discover that renting specific pieces of equipment during peak production periods makes far more financial sense than purchasing everything they might occasionally need.

The right heat treatment equipment is an investment in multiple areas of your business, like your quality standards, your workers’ safety and your reputation with customers. The benefits extend past the heat treatment process and affect your entire operation.

At Red-D-Arc, we’ve been supplying welders and fabricators with access to quality rental equipment for years, and we know that each project comes with different requirements. Our equipment catalog covers everything you might need, like welders, positioners, protective gear and specialty heat treatment equipment. Some customers need equipment for a single project, and others want to test different models before they commit to a purchase – we have rental options that work for either scenario. You can also check out everything that we have at Red-D-Arc.com and learn how our rental options will support your next welding project with the right tools and total confidence.

Leave a Reply