Recent Articles

Stay updated with our latest insights in welding, featuring expert tips, company news, product discussions and more.

Filter

Red-D-Arc 70th Anniversary Spotlight: Natalia Gusakov

In this 70th Anniversary Spotlight, Natalia Gusakov, Manager of Financial Planning & Analysis at Red-D-Arc, reflects on her journey with Red-D-Arc since 2017, highlighting the collaborative culture,…

Red-D-Arc 70th Anniversary Spotlight: Joe Holloway

As part of Red-D-Arc’s 70th anniversary celebration, we’re spotlighting Joe Holloway, VP of Automation, whose 30+ year journey with the company reflects a deep commitment to innovation…

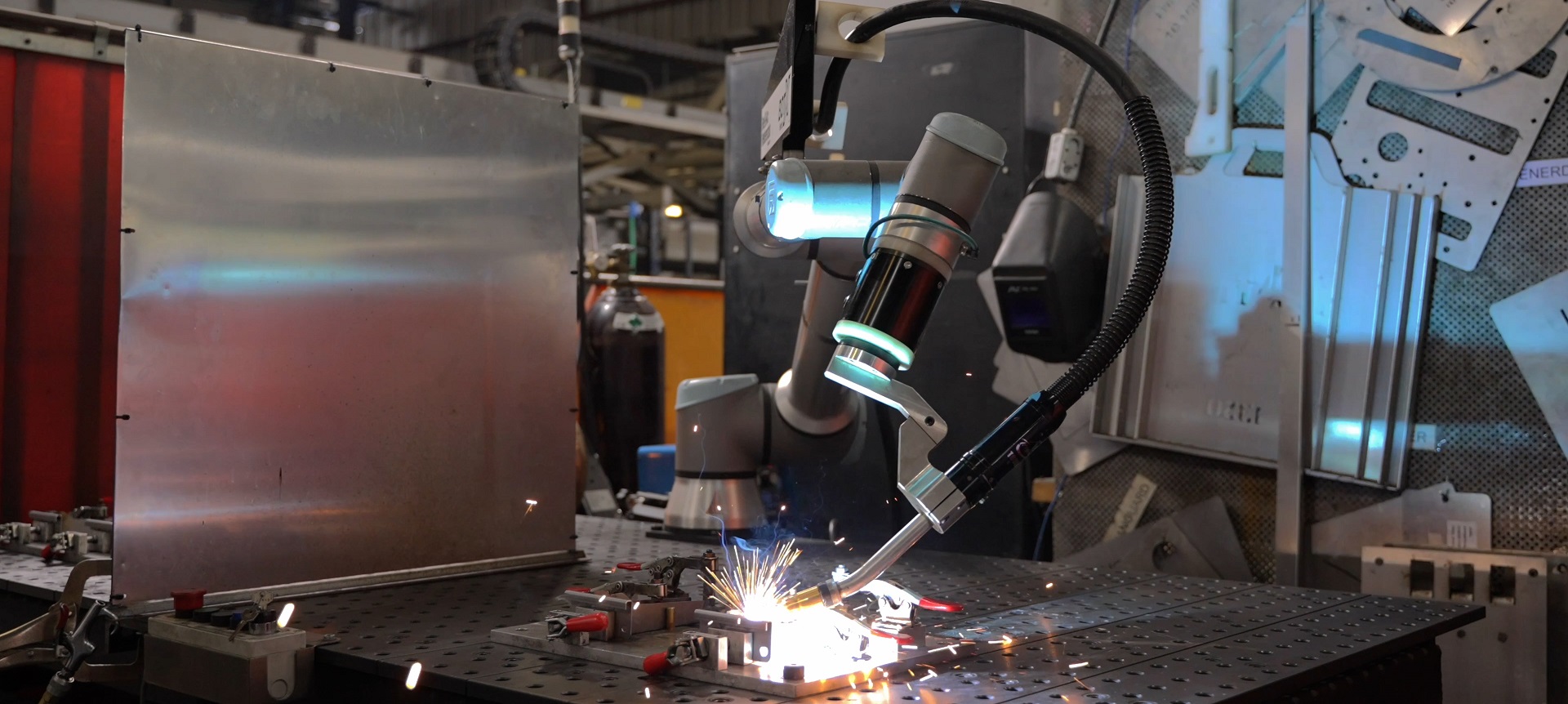

Welders Wanted: How Cobots Are Bridging the Skills Gap in Manufacturing

Facing a shortage of skilled welders, manufacturers are turning to collaborative robots (cobots) to boost productivity and quality. Working safely alongside humans, cobots handle repetitive welds with…

Celebrating National Welding Month with Red-D-Arc Weld Automation Specialist, Frank Carbone

In celebration of National Welding Month, Red-D-Arc highlights Weld Automation Specialist, Frank Carbone’s 30-year journey from electrical engineering to welding innovation, offering insights on industry evolution, workforce…

What is a BotX™ Cobot Welding System

The Growing Challenge in Modern Welding The recruitment and retention of skilled welders presents a persistent challenge for employers. Furthermore, experienced welders often dedicate valuable expertise to…

Red-D-Arc’s Port-A-Weld System: Revolutionizing On-Site Welding

When welders want to lay down perfect weld beads, they will turn to using a welding manipulator. These are perfect for welding on sections of pipe or…

The Arc Reach Heater Makes On-Site Heat Treatment Fast and Easy

The efficiency and precision of on-site heat treatment can significantly impact project timelines and overall quality of work. The Arc Reach Heater provides an innovative solution for…

Innovations in Stud Welding: Spotlight on Tru-Weld TW6900

Learn about the advanced features of the Tru-Weld TW6900, a heavy duty stud welding system known for its high power output, digital precision, and adaptability, making it…

The Auto-Set Feature: What Does It Do on MIG Welders?

Are you looking for an easier way to manage MIG welding? Whether you’re new to welding or a seasoned professional, the Auto-Set feature on MIG welders could…

Contact Us

Connect with your local Red-D-Arc sales team or our other welding industry experts by using this form.