Induction heating is a modern approach to supporting the welding process with preheat and post-weld heat treatment (PWHT) as well as other industrial tasks such as coating removal and placing or removing shrink-fit components. Although the conventional use of induction heating is limited to magnetic base materials, applications capable of using the process can reap significant operational savings and benefits compared to “conventional” heating processes such as flame/torch or even resistive heating. Could you be a good candidate for implementing induction heating into your welding or industrial maintenance processes? Shown here are just a few target use cases.

You Are Tasked with Improving Operational Efficiency and Safety

Heating components with fuel or oxy-fuel torches is a time-tested method, with an array of fuel gases and torch setups available to allow scaling to the application. Of course, torches and fuel gases present an inherent burn, fire, and explosion hazard. An alternative—resistive heating—has elements that reach significant temperatures and must cool before repositioning.

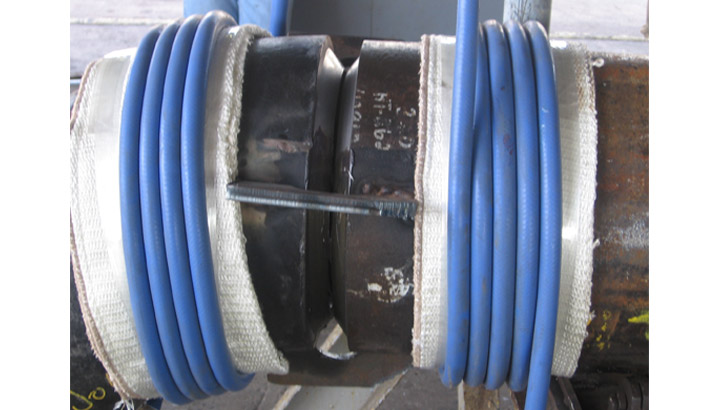

Many of the safety concerns present with conventional methods of heating are simply not present with induction heating. Instead of directly generating heat, the equipment induces eddy currents within the component that, in turn, cause heat to radiate outward from the center of mass. In most cases, the insulated induction heating blankets remain cool to the touch as the underlying component is heated. Using welding as an example, induction heating allows welding to occur as the equipment remains in-place. When welding is complete, the equipment can be quickly and efficiently repositioned to the next weld joint.

The nature of inductance heating also makes it a much more thermally efficient process compared to resistive and torch heating. A thermally efficient process is a cost-effective process. Remember that any joule of energy that does not actually heat the part (lost to heating the atmosphere, for example) is wasted time and money.

You Are Welding Thick and/or High-Strength Low-Alloy Steels

The primary purpose of preheat is to help slow the cooling rate of the weld zone to prevent the formation of brittle microstructures in the heat affected zone and weld metal. As such, preheat is not an operation that should be shirked, especially when high cooling rates cannot be avoided (as is the case with thick materials) or when the detrimental effects of high cooling rates are amplified (as is the case with high-strength low-alloy steels).

Similarly, certain high-strength low-alloy steels—such as the chrome-moly steels—virtually require some degree of post-weld stress relief to deal with residual stresses to keep the risk of cracking low. PWHT typically occurs at much higher temperatures than preheat application. Temperatures greater than 1050 degrees Fahrenheit are common and required ramp up and ramp down means that a great deal of energy, time, and attention is required.

Fortunately, induction heating with modern equipment is a smart process. After installing a few thermocouples to the component, pre-heat and post-weld stress-relief can be “fire-and-forget”. It is possible to program the equipment so that the desired interpass temperatures and PWHT ramp rates can be maintained by the equipment automatically. This is significantly preferable to making frequent checks with temperature indicating crayons.

It is possible to accomplish both preheat and post-weld stress-relief with the same induction power source, although specialized induction heating blankets are often required to handle the temperatures of post-weld stress-relief.

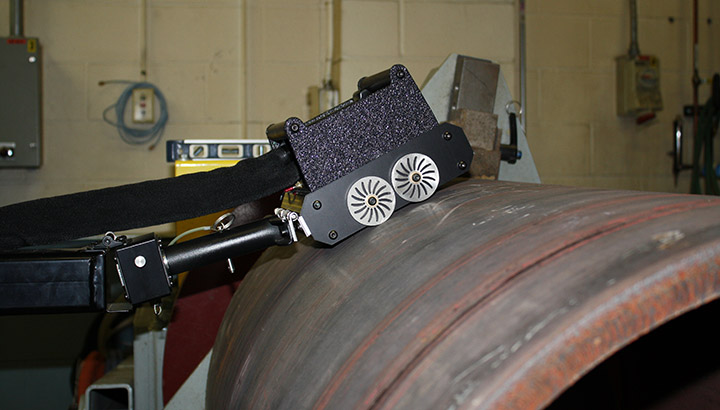

You Have High-Volume Heating Requirements and/or Large Components

Some components require shrink-fit installation and removal. Often, the component to be removed is a small part of a larger sub-assembly. In these situations, movement of the entire component—and use of a furnace for heating—is impractical. Induction is advantageous because modern equipment is relatively portable and both quickly and safely deployed.

In-service repair of other components may require the removal of coating often after they have been applied over a large surface area. Conventional methods of coating removal such as chemical stripping poses health and safety concerns in the working environment, while sandblasting generates a large volume of particulate that must be dealt with.

Because parts heated with induction generate heat from within the component that then radiates outward, certain coatings will disbond from the substrate when induction heating is used. This is known as induction stripping. As the coating disbonds, simple mechanical methods of removal such as chipping or scraping can be employed to strip coatings in large chunks or sheets.

Don’t See Your Application Above? Ask An Expert!

The above collection of induction heating use-cases is far from exhaustive. This is because induction heating is so versatile when localized heating of magnetic base metals must be performed. Even within the inductive heating world, there is a wide variety of equipment options that can help custom-tailor equipment performance and realized benefits. Experts at welding rental suppliers are more than willing to help you to select the best equipment for your application.