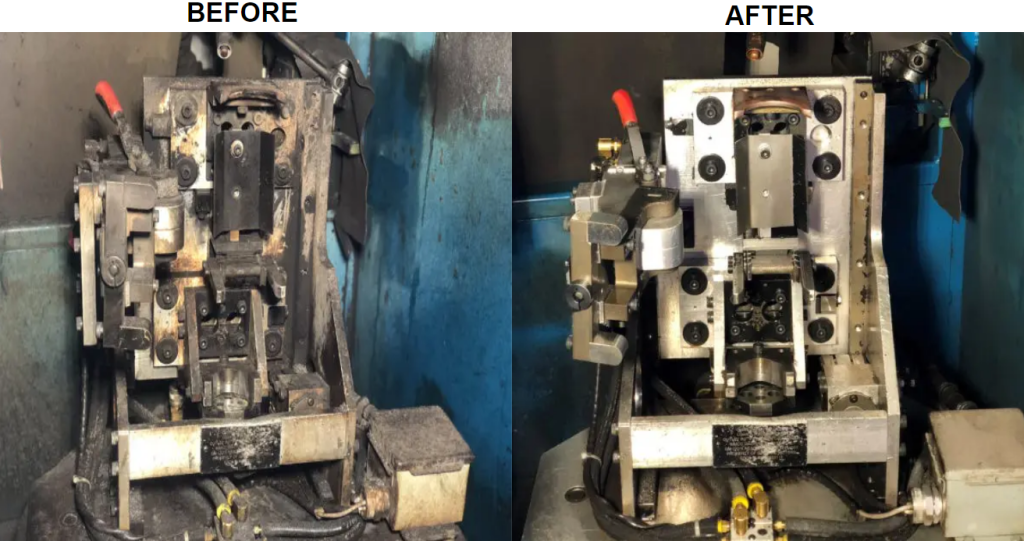

Weld spatter, resin, smoke, dampening adhesives, and other carbonized deposits pose continual challenges in fabrication, automotive, and manufacturing environments, gradually contaminating robots and surrounding production equipment. Without proper maintenance, these accumulations lead to misalignments, subpar welds, increased scrap rates, and decreased operational efficiencies. Enter dry ice blasting—a revolutionary cleaning solution perfectly suited for maintaining cleanliness in robotics, automated weld lines, fixturing, tooling, and intricate machinery requiring specialized care.

The various advantages of dry ice blasting include:

- Minimized production downtime

- Mold disassembly becomes unnecessary

- Superior cleaning ability, even in hot and confined spaces

- Elimination of waste disposal costs

- Increased operational uptime

- Non-abrasive, preserving the integrity of tooling

- Environmentally responsible, leaving no harmful residue

- Produces impeccable, as-cast finishes

Moreover, dry ice blasting offers a carbon-neutral, non-toxic alternative that aligns seamlessly with sustainability initiatives and proactive maintenance strategies.

In contrast, traditional manual cleaning methods pale in comparison:

- Labor-intensive and time-consuming

- Results in prolonged equipment downtime and revenue loss

- Poses risks of equipment damage, jeopardizing asset longevity

- Diverts skilled labor from more valuable tasks

Dry ice blasting revolutionizes cleaning and maintenance practices, enabling ‘clean-in-place’ capabilities, thereby eliminating the need for equipment disassembly or recalibration. Its non-abrasive nature ensures the safety of sensitive machine components, such as photo eyes and electricals, while mitigating misalignment-related performance issues. With only one operator required, dry ice blasting outperforms manual cleaning in terms of efficiency, safety, and efficacy.

The applications of dry ice blasting are extensive and adaptable, addressing cleaning needs across various equipment and components.

Common applications include:

- Fixturing and tooling

- Transfer cases and proximity switches

- Electrical components and cabinets

- Cabling and ancillary equipment

- Weld tables, positioners and trunnion systems

- and most other equipment or components that require cleaning

The Red-D-Arc team of dry ice blasting specialists are positioned nationwide and can tailor a turnkey rental solution that fits the needs of your next maintenance cleaning, deep clean, equipment refurbishment, or upcoming shutdown.

Leave a Reply