An undersized generator will shut down your welders right in the middle of a bead, and it’ll trip your breakers every time that multiple operators strike their arcs at once. Go too big with your unit and you’ll burn through the fuel way too fast as you rack up rental costs that you could’ve avoided – all as it runs at a partial load that’s pretty inefficient.

Multi-welder job sites need a different amount of power than the single-operator setups do, and most of the sizing mistakes happen if you try to treat them the same way.

Let’s talk about how to choose the right generator size for your welding operation.

Add Up the Power You Need

Your first move is to work out how much power your welders pull from the generator. Manufacturers don’t all list this the same way – some use kilowatts, others go with kilovolt-amps, and some just stick with plain old amps.

The conversion from kilowatt-amps (kVA) to kilowatts is pretty simple. For most applications, multiply your kVA by 0.8 to give you a working number for your calculations. Having an amp rating instead of kVA means the process needs one more step. Multiply the amps by the voltage to get watts, then divide it by 1,000 to convert it into kilowatts.

Once you’ve figured out the kilowatt rating for each machine on your site, you just add them up. Welder one, welder two, and welder three, and you continue until you have your grand total. That number represents the maximum power draw you’d see if every welder were running at full blast all at once.

A pipeline crew had five 300-amp welders on a job and needed to work out how much generator power to rent. They added them all up and assumed they’d all be running at maximum capacity at the same time. Well, they did just that, and the generator they rented turned out to be way bigger than what they actually needed once the work got underway.

Welders don’t run at full power the whole time. Operators cycle them on and off as they move through each section of their work. The arc fires up and holds for a bit, and then stops as they reposition or swap out the materials. That start-stop pattern matters in how you need to size your generator for different conditions.

The basic addition method will give you a starting point and show you the theoretical maximum load. The problem is that it doesn’t account for how welders actually operate in the field, which means you’ll probably wind up with a generator that’s bigger and more expensive than what you need.

Key Stats That Show Why Proper Sizing Matters

- A typical 120V welder pulling 20–30 amps requires 2,400W–3,600W running power, but needs 25–30% extra surge capacity for arc starts.

- A 240V welder drawing ~32A requires approximately 7,000W running and up to 9,100W peak during startup.

- Multi-welder job sites commonly require 10,000–15,000+ watts depending on the number of welders and auxiliary tools being used.

- Voltage fluctuations from low-quality generators can cause weld porosity, unstable arcs, machine faults, and premature equipment wear.

- Three-phase or heavy-duty industrial generators provide better stability for inverter welders and multi-operator setups.

Why You Need Less Power Than Expected

Duty cycle rating is one of the main specs to look at when you shop for a welder. A machine rated at 60% duty cycle can weld for 6 minutes in every 10-minute period before it needs to cool down. The other 4 minutes give the welder a chance to rest and drop back down to a safe temperature. Most welders fall somewhere in the 40% to 80% duty cycle range, and where they land depends on how big the machine is and how the manufacturer built it.

This alone cuts down on the amount of power you’ll actually need. Another part of it also comes into play here.

Multiple welders on a job site hardly ever all run their arcs at the exact same time. One guy might grind down a joint as another gets ready for his next piece. Another guy could head back to the truck for more rod or maybe just take a quick water break. This pattern actually has a name in the welding world, and it’s called the diversity factor.

For smaller crews, the industry benchmark tends to hover around 70% to 80%. On a site with five welders, that means only about three or four of them actively strike an arc at any given time. The others are in between tasks or getting ready for what comes next.

Bigger crews will see the diversity factor drop even lower. On a site with ten or twelve welders, it’s probably closer to 60%. The reason for that comes from coordination – with that many guys on the job, everyone spends more time waiting between their own weld passes.

Once you take both of these into account, they’re going to bring your generator size way down from what you first calculated. A welder that pulls 50 amps at max load will probably only average around 30 amps when you consider the duty cycle and the fact that it won’t run all day. Apply that same logic to your whole crew and you’ll see the total power needs drop pretty fast.

Which Generator Voltage Works Best for You

Once your operation has around four or more welders on the site, 480V systems will make much more sense for you than sticking with 240V. The benefits start to add up at that point.

Higher voltage has a benefit – it lets you use much smaller gauge wire to carry the same amount of power around. As the voltage goes up, the amps actually drop down. With fewer amps through those cables, you can use thinner wire, and you won’t have to worry about it overheating or losing any power along the way.

The job sites where everything is spread out make this a bigger deal. Weld stations are usually set up a few hundred feet away from wherever the generator is parked.

Run the cable at 240V over that distance, and the voltage drop gets to be a big problem that can hurt your weld quality and how well your equipment performs.

Steel fabrication yards have known about this for years – most of them switched over to 480V systems a while back for this very reason. Many shops were able to cut their copper costs by more than half just from the voltage change. What they saved on wire alone actually covered the entire cost of the conversion in some cases.

Foreman’s Job-Site Generator Checklist

- [ ] Collect electrical specs for every welder (voltage, amps, plug type)

- [ ] Calculate total site wattage (running + surge for each unit)

- [ ] Add auxiliary equipment (lights, grinders, ventilation)

- [ ] Confirm generator has 20–30% overhead capacity

- [ ] Verify generator offers stable, low-THD power

- [ ] Ensure cabling is correct gauge to avoid voltage drop

- [ ] Plan safe distribution (panels, breakers, cords)

- [ ] Check fuel availability + run-time for long shifts

- [ ] Perform daily checks: oil, filters, cables, warnings

- [ ] Assign a power supervisor for multi-welder coordination

The voltage you choose will also have an effect on your safety margins, and that’s worth keeping in mind. A 480V system at around 70% of capacity behaves quite differently from a 240V system pushed near 90% of capacity. Both deliver the exact same welding power for your project. Where it gets interesting is in how they each take care of the heat buildup and load stress.

You’ll want to review your options before you buy a generator. A 480V unit will cost you more money at the start, no question. But the wire savings and improved performance can help balance out that higher price tag, especially when you’re running multiple welders every day.

Plan for Extra Equipment and Power Needs

Welders are power-hungry machines, and plenty of other tools on a job site will pull just as hard from your generator. Grinders are a big one to factor into your power planning. Each grinder creates massive startup surges, and a generator without enough capacity will get overwhelmed pretty fast.

Compressors are another factor to account for. They cycle on and off all day long, and each time they fire back up, they pull hard on your power supply. Night work brings work lights into play as well. Battery chargers for cordless tools are easy to miss – each one doesn’t draw much power on its own. But if a few charge at the same time, the load piles up fast.

Job sites run into problems when equipment shows up that wasn’t part of the original plan. Maybe somebody brings in a plasma cutter that wasn’t on the list. Or a crew fires up a weld preheater without telling anyone. Highway bridge crews know this problem well – those preheaters pull massive amounts of power.

Extra capacity from the start will keep these situations from being a big problem. An extra 20 to 30% gives you plenty of breathing room when unexpected equipment shows up on the site. This buffer keeps your generator from getting overwhelmed when multiple pieces of equipment all pull power at once.

Every tool and device that might get plugged in during your workday needs to be on your list. Write everything down when you have lots of equipment to track, so you remember everything. The point is to figure out your total power requirements before you pick one generator over another.

How to Estimate the Generator Size You Need

To size a generator for multiple welders, use this simplified formula:

- Check each welder’s input amps × volts = running wattage

- Add 25–30% surge capacity for arc starts

- Add auxiliary tools (grinders, lights, compressors)

- Size above your maximum expected load to prevent overload

- Consider three-phase power for multi-operator setups

Single Large or Multiple Small Generators

After you calculate your total power requirements, the next question is pretty simple. You can go with one large generator that covers everything, or you can use a couple of smaller units that run together.

Multiple smaller generators actually give you some benefits over a single large unit. Say that your calculations might tell you that you need around 200kW of total capacity. In this situation, you could go with two separate 100kW generators instead of one massive single unit. If one generator goes down for maintenance or breaks down completely, you’ll still have the other one running, so at least part of your crew can stay on the job. That backup protection can save your entire timeline from falling apart.

Another benefit comes into play if you only have a few welders on site for the day. With just a handful of machines running, you can get by with one generator instead of having to run both of them. Fuel efficiency might not sound like a big deal. But generators work much better when they’re operating close to their rated capacity. A 200kW generator that’s only supplying 50kW worth of welding equipment is going to waste too much fuel and run pretty inefficiently the whole time.

Smaller units are easier to work with if you need to move them between job sites. A pair of 100kW generators will fit on standard trailers, and they can get through gates that would stop a single large unit. Even better, your crew can split them up and send one generator to a different location if two jobs are running at the same time.

Plenty of commercial contractors have made the switch to this setup after spending years hauling oversized generators from one job site to the next. What most of them found was that they were stuck running the units at only 30% or 40% of capacity on an average day. The fuel costs piled up fast, and the engines took on a lot more wear than they should have. When they split that same total capacity across two or three smaller generators, those problems disappeared, and they got the backup redundancy they needed to stay on schedule.

When Are Combo Units Right for You?

Some job sites are a perfect match for machines that combine a welder and generator into one single unit. Combo machines work great if you have a crew of two or three welders who all need to get to remote locations. You don’t want to haul separate equipment around when you’re miles away from the nearest road, and it’s a pain in the neck.

Pipeline repair crews use these combo units a lot because they need to weld out in the field where there’s just not much infrastructure to support them. Farm fabricators are also big fans of this setup since they’re usually working nowhere near any buildings or any reliable power source. With everything built into one machine, you’re hauling around way less equipment, and it takes way less time to get it set up each morning.

You get simplicity and portability, and that can really help depending on the type of work you do. What you’re giving up is the flexibility in how you allocate power across your team. A standalone generator lets you run multiple welders at the same time or move power between different tools as the work changes during the day. A combo unit locks you into a fixed setup, and on bigger projects, that limitation can really hold you back.

The right choice for your operation depends on your work environment and how big your crew is. Bigger teams usually need to power the other equipment alongside their welders, and a standard generator (like the ones I talked about earlier) is going to be the way to go. Small crews are a bit different, though. An all-in-one welder generator is probably the better option for what you’re doing if you need to move around frequently and you’re not planning to expand your setup.

Where The Pros Get Their Welding Rentals

A solid power setup on a multi-welder job site isn’t something you want to guess at and hope it all works out. I always recommend a simple calculation that takes the mystery out of it. First, add up the total load requirements across the welders you’re planning to run on site. Then you’ll need to apply what are called diversity adjustments to that total (and this part makes sense because all your welders won’t be firing at maximum capacity at the exact same time). When you have that adjusted number, you can pick the voltage level that makes the most sense for your particular operation, add in a safety margin to account for any unexpected demand spikes and make a final call on whether you want one big generator powering everything or multiple smaller units spread across the site. This calculation, when done correctly, lets your welders stay focused on turning out quality work without power dips or interruptions to break their concentration and ruin a clean bead, and it also means your generators will run in their optimal efficiency range instead of lugging along under too much load or burning excess fuel because they’re oversized for what you actually need them for.

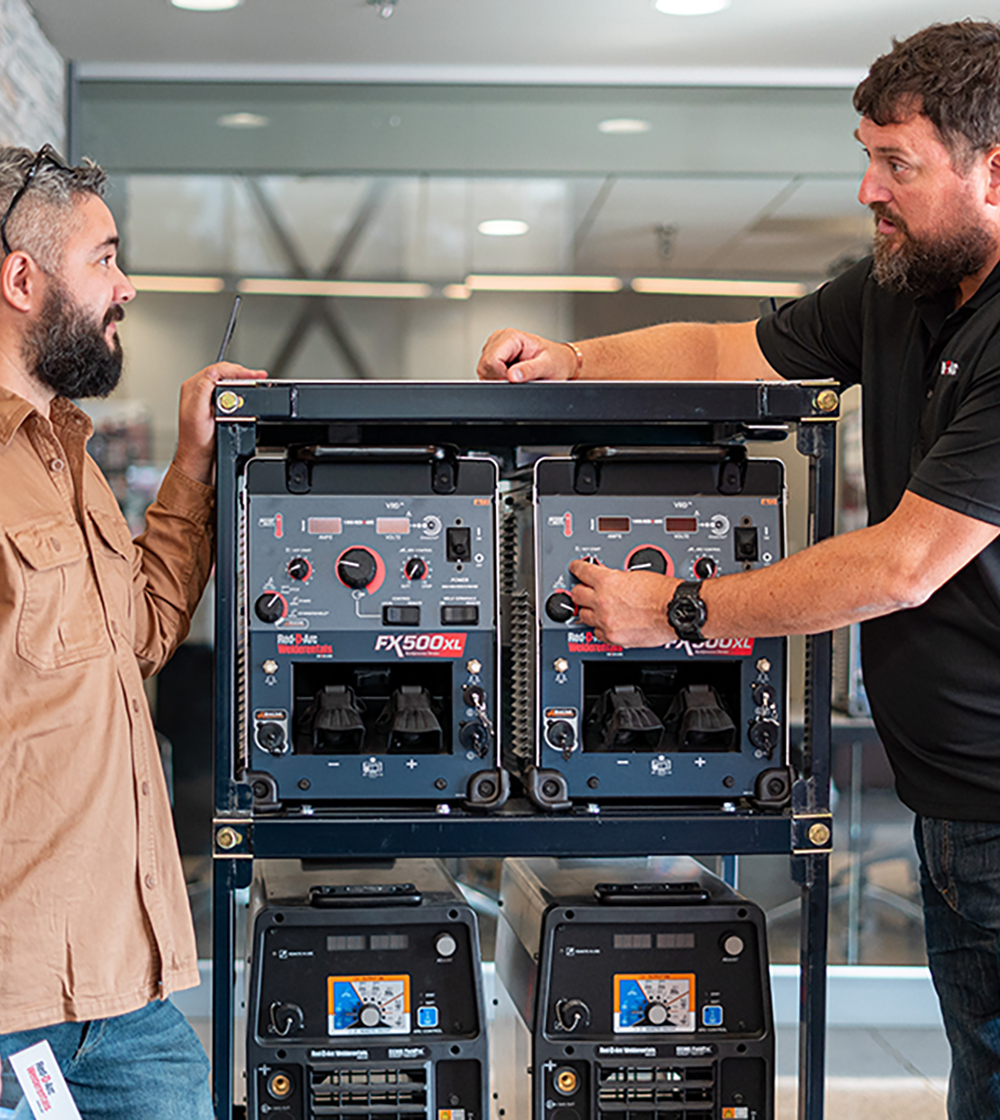

Red-D-Arc’s Generator Fleet

- Heavy-duty industrial-grade gensets: Red-D-Arc generators are engineered specifically for welding applications, unlike general-purpose commercial generators.

- High surge capacity: Ideal for arc starts, simultaneous loads, and multi-machine operations.

- Stable voltage output: Helps prevent weld defects and protects sensitive inverter welders.

- Large multi-operator models available: Red-D-Arc’s generator lineup includes units capable of powering several welders at once.

- Tested for rugged job-site conditions: Designed for construction, industrial, and fabrication environments.

- Backed by expert support: Red-D-Arc specialists can size equipment for your exact job-site requirements, reducing guesswork.

Getting your power needs wrong is going to cost you money either way. Pick a generator that’s too big, and you’ll burn through extra fuel every day of the project, and you’ll also be paying rental fees for capacity you don’t even need. Pick one that’s too small, and you’ll have a different mess on your hands – one that will slow down your crew and create expensive delays. Your welders won’t be able to run their equipment the way they should, breakers will trip throughout the day, and everyone on the job site will get frustrated working around a power system that can’t handle what needs to be done.

Following these steps lets you avoid the common mistakes that show up on job sites where you have multiple welders all running at once. Your equipment is going to match what your crew actually needs, your project timeline won’t get derailed, and you won’t be wasting money on power capacity that never gets used or putting up with frequent problems from not having enough power to work with.

At Red-D-Arc, we’ve been a trusted name for welders who need reliable rental equipment that works when it arrives. Our inventory includes everything from welders and generators to positioners and the protective gear your crew needs – and we make sure it’s all serviced so you can be sure it’ll perform when you need it. When you need to rent or buy equipment for your next job, visit Red-D-Arc.com to check out our full catalog and get just what you need.

Looking for diesel generators

Choosing the right generator for multi-welder job sites is essential for ensuring efficiency and effectiveness. By understanding your power requirements and selecting appropriate equipment, you can optimize your workflow and maintain productivity. Trust Red-D-Arc to provide you with high-quality, serviced rental equipment tailored to your project’s demands. For a comprehensive selection of welders, generators, and accessories, visit Red-D-Arc.com today.

Leave a Reply