The demand for high-quality, high-volume cutting is relentless. Shops are constantly striving to reduce downtime, minimize rework and address the persistent skilled labor shortage. The solution lies not just in automation, but in collaborative automation which combines the speed and precision of robots with the ability to keep your skilled team engaged by allowing them to complete more challenging, high-value work.

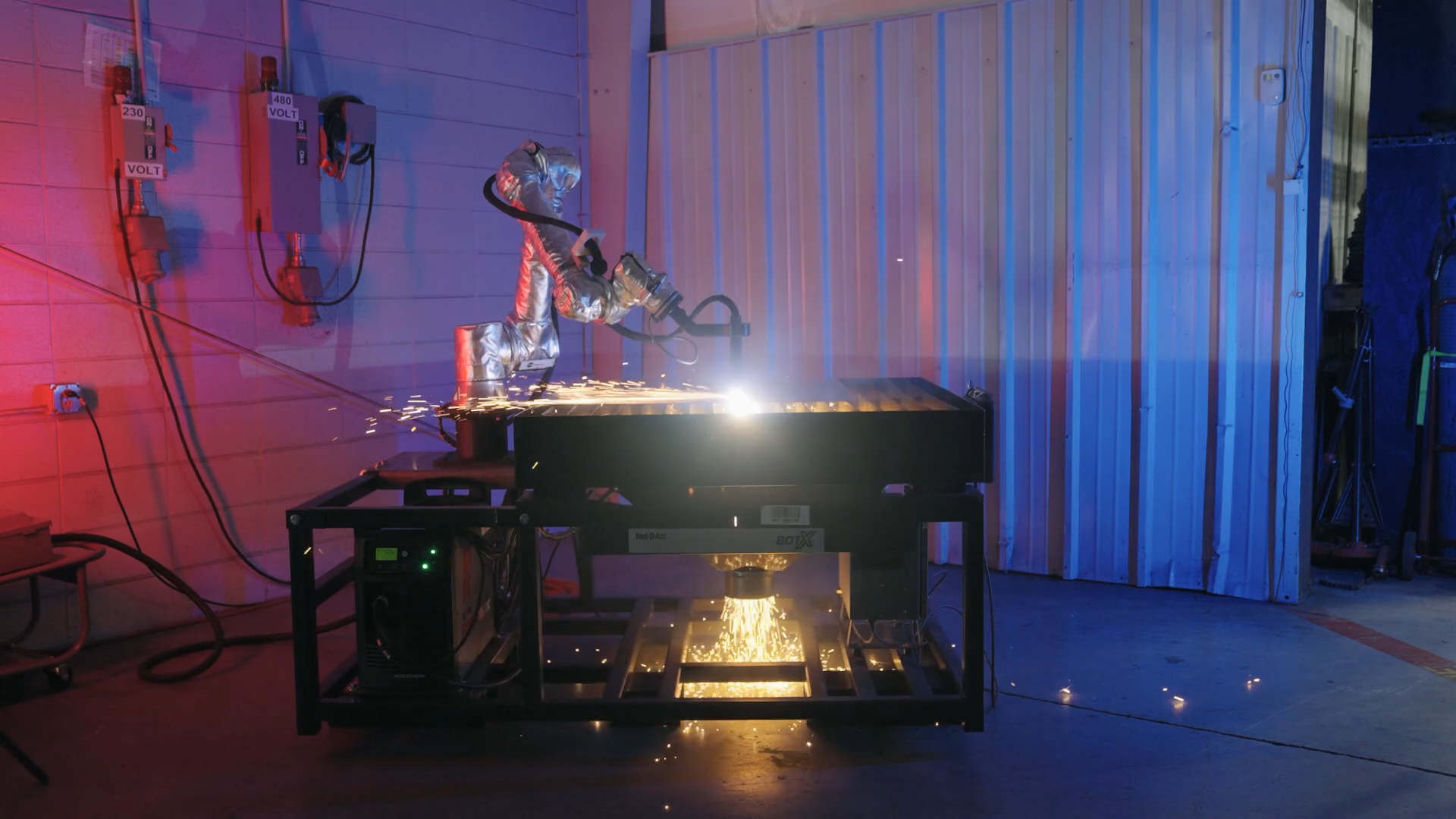

Red-D-Arc, a leader in welding and cutting equipment solutions, is answering this need with the revolutionary BotX™ Plasma Cutter. This cobot (collaborative robot) system delivers the speed and precision of industrial robotics with the simplicity and flexibility that modern fabricators require.

Discover the BotX plasma system’s game-changing features and how Red-D-Arc makes this advanced technology accessible to your business through flexible acquisition options.

Precision Meets Simplicity: Game-Changing BotX Plasma Cutter Features

The BotX Plasma Cutter is engineered to dramatically boost your uptime and quality by taking the complexity out of automated cutting.

1. Rapid Programming and Setup

Traditional robotics often require days of specialized programming. The BotX plasma cutter changes that.

- User-Friendly Interface: The system features an intuitive interface that simplifies programming. Operators can be trained in a matter of hours, allowing you to start cutting new parts in as little as 5 to 10 minutes, compared to hours with conventional robots.

- Dual-Path Teaching: Program parts instantly by manually teaching the cut placement, or maximize control and efficiency by importing precise CAD drawings.

2. Unmatched Versatility and Accuracy

The BotX plasma cutter is designed to handle complex geometries and materials that challenge standard CNC tables.

- 2D and 3D Capabilities: Effortlessly cut flat stock, but also conquer challenging shapes like domes, structural beams, and pipe coping, opening up new fabrication possibilities.

- Integrated Laser Sensor: The system uses an integrated laser sensor to quickly scan part surfaces and edges with incredible accuracy—down to 0.01mm.

- Stingray® Torch Height Control: This technology maintains a precise cut-height throughout the process, ensuring consistent, high-quality cuts and ultimate part accuracy.

3. Revolutionary Mobility and Configuration

The ability to move the cutting system to the material, rather than the other way around, is a major productivity advantage.

- Detachable Magnetic Base: The innovative optional magnetic base allows the cobot to be positioned away from the cart, locking securely onto any compatible ferrous material—even on vertical or curved surfaces. This versatility is critical for large or fixed workpieces.

- Flexibility: Select your choice of Universal Robots (UR) cobot arm from the UR10e, UR20 or UR8L, offering a reach of up to 68.9 inches.

- Power: The BotX plasma cutter is compatible with a range of powerful Hypertherm® power sources: Powermax85 SYNC™, Powermax105 SYNC, Powermax 125 and MAXPRO200.

- Hypertherm SYNC Technology: This integration — available on systems paired with either the Powermax85 SYNC or Powermax105 SYNC — drastically simplifies maintenance by utilizing revolutionary single-piece cartridge consumables, which are fast to change and help reduce material waste.

Zero Risk, Maximum Output: Red-D-Arc’s Flexible Acquisition Options

Red-D-Arc understands that capital investment can be a bottleneck. That’s why they offer unparalleled flexibility to integrate the BotX plasma cutter into your operations with minimal risk.

| Acquisition Option | Best For | Key Benefit |

|---|---|---|

| Rent | Short-term contracts, urgent projects, or immediate capacity demands | Maximize productivity while avoiding upfront capital costs |

| Lease | Long-term use with lower monthly payments | Stabilize costs and treat the system as an operating expense |

| Purchase | Permanent adoption for high-volume, long-term use | Full ownership and long-term asset utilization |

The Red-D-Arc Advantage: Try Before You Commit

Red-D-Arc offers a “Try Before You Commit” program, allowing you to experience the BotX plasma cutting system in your actual production environment first. If you decide to convert your rental to a lease or purchase within the first two months, Red-D-Arc will credit 50% of your rental cost toward the new agreement.

Combine that with white-glove installation and training on your site plus fast remote support provided by welding specialists, and Red-D-Arc ensures that you are running productively from day one.

See the Future of Plasma Cutting in Action

Ready to see how fast, flexible, and precise the BotX Plasma Cutter can be? Watch the official product video to see the cobot in action, demonstrating its intuitive programming, flexibility and precise cutting capabilities:

Contact our team to get started today

Contact a Red-D-Arc specialist today to discuss a rental, lease, or purchase plan customized for your shop’s needs and start revolutionizing your fabrication process.

Leave a Reply