Welders who need information about turning rolls usually wade through endless technical specifications and model numbers. Many professionals in the welding industry run into this same confusion when they first come across these machines. The vast number of different types of equipment available can be overwhelming. Every model works a bit differently.

The first time you walk into a shop and see a 30-ton vessel rotating on massive steel wheels as sparks fly from welding torches all around it, you’ll immediately think about safety and control. These machines are impressive – they can work with workpieces that range from small pipes all the way to tanks that span 30 feet in diameter. Despite their importance and sophistication, though, most operators will get almost no training. They might learn where the on/off switch is and maybe a few basic controls, and then they’re expected to position multi-ton cylinders for precise welding work.

I want to show you how you can run these systems safely and efficiently, whether you’re working with compact pipe stands that can support 2,200-pound loads or massive industrial tank rolls that can support 90,000-pound vessels. The core principles are actually the same across the board, and we’ll go step by step from your first setup all the way through to troubleshooting those problems that even experienced operators run into from time to time.

Let’s go over all the basics of turning rolls and how to use them properly!

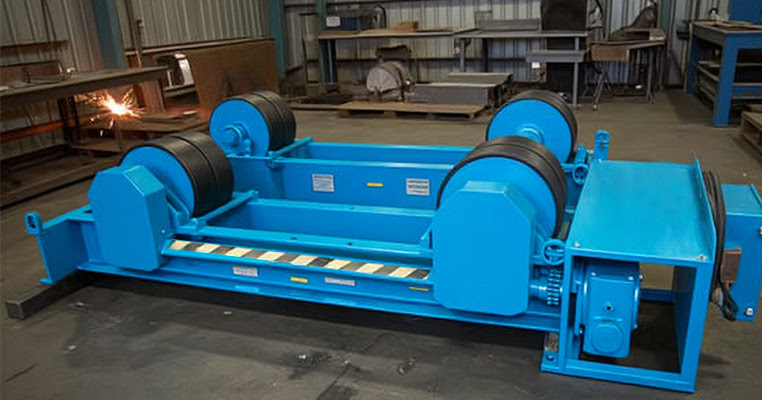

The Parts of a Turning Roll System

A turning roll system can seem pretty hard to understand at first, especially if you haven’t worked with one before and you’re seeing all the mechanical parts for the first time. The whole setup gets much easier once you understand what you’re looking at.

The drive rolls are the heart of any turning roll system because they’re the powered wheels that actually rotate your pipe or tank at whatever speed you need for your welding job. Then you have the idler rolls that sit on the opposite side and spin freely as they support the weight of your workpiece. The drive rolls do all the work of rotating the piece, and the idler rolls just support the weight and rotate along with whatever the drive rolls are doing.

Most manufacturers make rolls with either rubber coating or bare steel surfaces, and both types have their place in different applications. Rubber-coated wheels are great because they grip your workpiece well, and they won’t scratch or damage delicate materials during rotation. Steel wheels are the better choice whenever you’re working with extremely hot parts that would just melt the rubber coating on contact.

The frame assembly is the main structure of the whole setup that holds all the rolls lined up right where they need to be and prevents everything from falling apart. The control panel is actually the command center for the entire operation. From there, you can dial in your rotation speeds and switch the directions whenever the job calls for it. Control panels run the gamut from basic manual setups with just a couple of knobs to advanced digital interfaces with programmable presets for different applications.

Motor configurations change quite a bit from one shop to another. Many shops run one large motor that powers multiple roll sets through a gearbox system for cost efficiency. Others buy separate motors for each roll set because it gives them way better control over rotation speeds.

Maintenance crews who’ve been around these systems for years will tell you that operators who know how each component functions usually experience about 40% fewer equipment failures compared to operators who just know the basics. It’s pretty logical, actually – proper maintenance is almost impossible if you don’t know what each part is supposed to be doing and how it all works together.

Basic Steps for Your Workpiece Setup

When you start to place any workpiece on the turning rolls, you need to take some time and calculate where the weight sits. A 10-ton tank on 20-ton rolls has the capacity on paper. But if you place it in the wrong spot, you’ll still get damaged equipment anyway. The weight has to be spread evenly across the two roll sets, and this really matters for safe operation.

Most shops follow a pretty basic guideline for this. You want to support your workpiece at approximately 30 to 40% from each end. This helps hold everything nicely balanced and prevents the middle section from sagging down or the ends from lifting up during rotation. Alignment is the next step to check. You need to verify that your rolls are parallel with a straight edge and level. Even a small misalignment will cause your workpiece to walk sideways as it rotates. Nobody wants to chase a moving tank across the shop floor.

One item that many shops completely forget to check is the electrical phases. These need to be correct, or the rolls will spin backward when you hit the start button. Experienced welders have been known to jump back when this happens. Take a few minutes to verify the rotation direction before you load anything heavy.

After your rolls are aligned and spaced the way they need to be, it’s time to set the workpiece in place. The main point is to center it on the wheels so there’s equal contact on each side. The vessel needs to rest without any force – if you have to push or wedge it in there, something’s wrong with your setup.

Speed Control Options for Your Machine

After you have your turning rolls all set up and ready to go, the next step is to learn how to actually run them. The majority of the units out there have variable speed controls, and these usually let you adjust the rotation anywhere from about 6 inches per minute all the way to 60. When you’re just getting started with a new workpiece, it’s best to begin at the slowest possible speed setting. That way, you don’t have to worry about the pipe or tank sliding out of position as you’re setting everything up.

What you want is to match up your rotation speed with your welding speed. When the rolls spin too fast, you get a weld that doesn’t penetrate deep enough into the metal for it to work right. But if they’re moving too slowly, all that heat gets concentrated in one place for too long. With thinner materials, especially, that excess heat is going to cause warping, or it will burn right through the metal.

Computerized positioning systems make a real difference for repetitive work. These systems let you program in the exact rotation sequence you need for a particular job, and then the machine remembers it for next time. This feature really pays off when you’re working on production runs where you need to weld multiple identical pieces one after another.

Experience is the best teacher for dialing in the right speeds for different materials. A 1/4-inch carbon steel plate is going to need a very different rotation speed than what you’d use for a thin stainless steel tube. Stainless steel is tricky to work with because it doesn’t dissipate heat the same way that normal steel does. You’ll need to bump up the speed when you’re working with stainless if you want to avoid those telltale color changes and to reduce distortion. I’ve seen too many welds ruined by heat distortion on stainless steel, and it’s always because somebody got the speed wrong.

Control systems for turning rolls usually fall into two main categories – pendant controls and panel-mounted interfaces. Pendant controls give you a big benefit since you can position yourself right next to the workpiece and adjust the rotation speed whenever you need to. Panel controls are a different story altogether – they’re permanently attached to the machine base, and that means you’ll be walking back and forth every time an adjustment is necessary. Wireless remotes have been catching on more lately in fabrication shops, and it makes perfect sense why. A wireless remote lets you manage the rotation from any place on your shop floor and saves a lot of time when you have massive vessels that need attention from multiple angles. The freedom to move around as you maintain full control over the rotation speed changes how efficiently you can work on big projects.

Safety Steps for Your Equipment Work

Working with turning rolls demands plenty of respect. Every shop has its own safety standards. But most of them call for a minimum of 6 feet of clearance all the way around the equipment whenever it’s running. Experienced operators know where these boundaries are, and they’ll usually mark them with bright-colored floor tape right on the concrete. The tape gives everyone a visual boundary that everyone can see, and it goes a long way toward keeping the whole crew safe during production runs.

The weight distribution of whatever you’re working on turns into a big safety factor if you don’t have the right support systems in place. Tailstocks and steady rests are absolutely necessary when working with long pieces or vessels with thin walls. Without adequate support underneath, the middle section of your workpiece will start to sag downward. This sagging will make the entire piece fall off the rolls. I’ve witnessed tanks that actually buckle and completely collapse because an operator decided they’d skip putting in a steady rest.

Every shop needs to have complete lockout/tagout procedures for roll maintenance work. Period. The shops that actually enforce these procedures consistently see their injury rates drop by around 85% and it’s a staggering improvement in workplace safety. The difference between following lockout procedures and skipping them could quite literally be the difference between workers heading home safely at the end of the day or requiring emergency medical treatment.

Runout is another big hazard to monitor, and it happens when your workpiece develops a wobble during rotation. The problem tends to show up frequently in busy shops. Once that wobble gets bad enough, the entire cylinder can eject itself right off the rolls. Production shops usually install emergency stop buttons at set intervals – maybe every 20 feet or so along the line – specifically to shut everything down fast when runout starts happening.

Foot protection needs extra attention in any area near turning rolls. Standard work boots just don’t give enough protection for this environment. Workers need steel-toed boots that are specifically rated for crushing protection from cylindrical objects because a pipe or tank that rolls off the equipment will absolutely crush an unprotected foot in an instant. Heavy-duty safety boots feel awkward at first, especially during long workdays. But the extra weight and bulk pay off in that split second when equipment fails and something heavy starts rolling toward you.

Problems That You Might Face

A workpiece sliding off the rolls usually happens more than it should, and fortunately, the fix is usually one of 3 basic adjustments. Wheel pressure should be your first checkpoint because, without adequate pressure, the wheels just can’t grab onto the material properly. Oil and grease buildup is the next most likely issue – the rubber wheels lose their ability to grip the workpiece when there’s even a thin film of residue on the surface. Weight capacity also matters quite a bit in this equation. Every machine has its maximum load specifications, and once you exceed those limits, the slippage becomes almost inevitable.

Pipes or tanks that slowly walk toward one end during rotation have an alignment issue. Roll height differences are usually to blame, and even the smallest variance can create this drift. The adjustments that are needed are fairly minor, usually just a few millimeters one way or the other. A patient, methodical leveling of the two ends will usually solve the walking problem completely.

Drive roll wear patterns can tell you quite a bit about what’s going on with your equipment. Uneven wear across the surface tends to indicate that the system is either overloaded or the rotation speed doesn’t match what you need. Maintenance departments that track these patterns have found that roughly 70% of their problems come from setup mistakes instead of the equipment breaking down.

Unusual sounds deserve immediate attention because your equipment is trying to tell you something worth paying attention to. Grinding noises or unexpected vibrations usually point to bearings that are beginning to deteriorate. The variable frequency drives on older systems are notorious for generating error codes at a higher rate than their newer counterparts. These electronic control problems can be somewhat tough to diagnose. But the actual fixes are usually simple once you look into the diagnostics.

Most turning roll problems actually aren’t nearly as hard as you’d expect. Every time you troubleshoot one of these machines, you pick up something new, and pretty soon, you’ll be able to diagnose problems without even thinking about it. The same patterns show up again and again, and what used to feel like a total mystery just turns into a part of your everyday maintenance work.

Where The Pros Get Their Welding Rentals

Turning rolls can be tough in the beginning. But the learning curve gets easier pretty fast, and once you get the hang of it, you’ll ask yourself why you waited so long to learn how to use this equipment. Those first few days are always rough when you work with these massive machines and try to figure out which button controls what and how all the different parts work together. Every skilled operator went through this exact same phase, though. The mechanical knowledge you’re slowly picking up, along with the setup routines you practice day by day and those solid safety habits you develop along the way – these pieces will eventually click together and create a strong foundation that you’ll depend on for the rest of your welding career.

After you’ve become comfortable with all the basic operations and understand how these machines actually work, you’ll start to see opportunities for projects that would have seemed completely out of reach just a few months earlier. Maybe you’ll work on heavier pipes than you’ve ever handled before, or you’ll handle longer tanks that need more precise control, or you’ll take on tough assemblies that need to rotate at exact angles and speeds. The basic principles remain the same when you operate a simple manual setup with basic controls or when you program an advanced system that has computerized interfaces and automated features. The skills and knowledge you’re developing now will carry over to whatever equipment you run into later.

Quality equipment makes all the difference in the world when you’re learning these techniques or when you’re ready to take on more advanced projects. At Red-D-Arc, we understand that most welding shops can’t simply buy all the equipment they might need for those times when you’re trying out turning rolls for the first time or when you’ve just won a contract that calls for specific machinery. Our rental inventory has everything from basic turning rolls all the way through to advanced positioners that have strong control systems, and we stock all the welders, protective gear and accessories that keep you safe and productive on the job. You can check out our full catalog at Red-D-Arc.com to find out what your project needs, and it doesn’t matter if you want a short-term rental for one job or if you’re thinking about adding permanent equipment to expand what your shop can do.

Leave a Reply