Pipe preparation is one of the decisions that matters most and can eat into your project budget if you get it wrong. We’re talking about 30-40% of your total welding time here, and the choice between renting beveling machines or doing the manual prep work could cost you thousands of dollars either way.

I see contractors fall into the same trap all the time. The manual option is familiar and predictable. Then you do the math on the labor hours, and consumables after you’ve prepped 50 joints, and the numbers get ugly fast. Machine rental runs expensive up front. It cuts your prep time by 60-70% and the productivity gains start to make more sense. You’ll find the project thresholds and cost break-even points that tell you which option will save you money. Project volume is where the analysis starts.

Here’s when renting makes sense versus sticking with your manual pipe prep methods!

How Project Size Determines Your Equipment Choice

The 50-joint threshold is actually a pretty reliable benchmark in the industry, and most contractors I work with usually agree on this one. After you cross that number of joints on a project, the economics of renting a beveling machine instead of relying on manual prep will become much more favorable.

The numbers themselves are fairly simple once you break them down. A decent beveling machine will usually get through a joint somewhere between 15 and 30 minutes. Manual preparation on that exact same joint usually runs you 1 to 2 hours, and that’s especially true if you’re working with schedule 40 pipe or any of the heavier wall thicknesses. When you have dozens and dozens of joints on a project, that time difference starts to compound in ways that affect your bottom line.

Turnaround projects are where the pressure shows up. Plants can lose millions of dollars in production revenue for each hour they remain offline, and suddenly, those time savings become essential to the success of the project. Manual prep with hand tools, as the facility sits idle, just isn’t a viable option in those situations.

The setup time for the machine does need to be a part of your calculations, though. Usually, you’re looking at about 2 to 4 hours to get the equipment delivered to your site and get it operational. That’s a decent chunk of time upfront. But the payoff comes pretty fast once your crew starts completing joints at a much faster pace. What many contractors don’t account for is the fatigue factor. They’ll calculate their prep times based on how fast their crew gets through the first five joints of the morning shift. This type of manual work is repetitive and exhausting, and your crew’s morning pace won’t match what they’re capable of by mid-afternoon.

The time savings look great once you run the numbers, and they usually are. But the financial benefit depends completely on the laws and constraints of your particular project.

What Manual Work Really Costs You

Those grinders and cutting discs you already own are just sitting there ready to go, and renting a machine seems like an unnecessary expense. Run the numbers – the whole picture changes pretty dramatically.

Beveling machines will run you somewhere between $500 and $1,500 per day to rent, depending on the model and where you get it. That price tag can make you pause if you haven’t done the math on what manual prep is actually costing you right now. Labor is the big one that many contractors underestimate. Even if you’re only paying your skilled workers $150 to $200 per day (and let’s be honest, skilled grinders usually cost more than that), you have to remember that it takes multiple workers to match what one machine can do. We’re talking about 2 or 3 grinders per workday just to keep up with the same pace as a single beveling machine.

Consumables are the hidden expense that kills budgets on manual prep jobs. A quality grinding wheel costs anywhere from $5 to $15 each, and they don’t last nearly as long as you’d hope. Large projects can eat through hundreds of these wheels, and the costs pile up in ways that most contractors never track properly. The purchases happen a few at a time, spread across different suppliers and invoices, so the total spend gets almost invisible until you add it all up at the end of the year.

The productivity difference is where the rental starts to make more sense. One operator running a beveling machine can usually match the output of 3 manual grinders, sometimes even more if the grinders are working on tough angles or thick-walled pipe. What that means for your bottom line is pretty simple – while you’re paying for the rental, your labor costs drop by over 60%. I’ve seen contractors cut their prep labor costs by 60-70% after accounting for the rental fee in their calculations.

Equipment costs alone don’t tell the full story. A $1,000 per day rental feels expensive when you’re signing the paperwork. But if you actually sit down and add up the labor hours, consumable costs and the productivity gains, the numbers paint a very different picture. The rental starts looking like the better financial move pretty fast. And this assumes that your manual bevels are perfect every time, and we all know that isn’t the case. Poor bevel quality causes weld failures, rework and inspection delays that can blow your budget in ways that make the equipment rental look like pocket change.

When You Need Machine-Level Precision

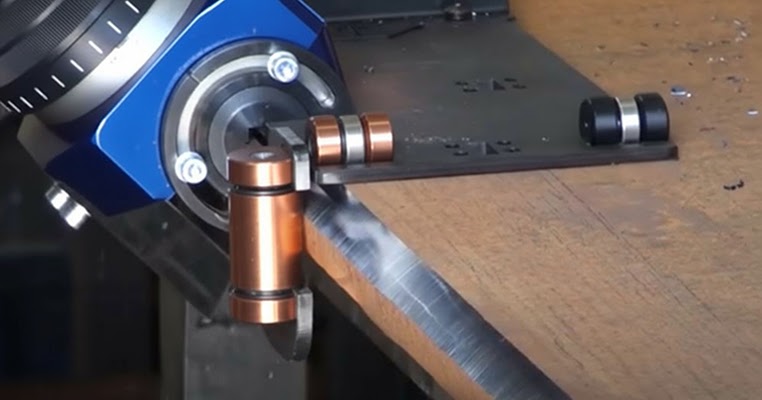

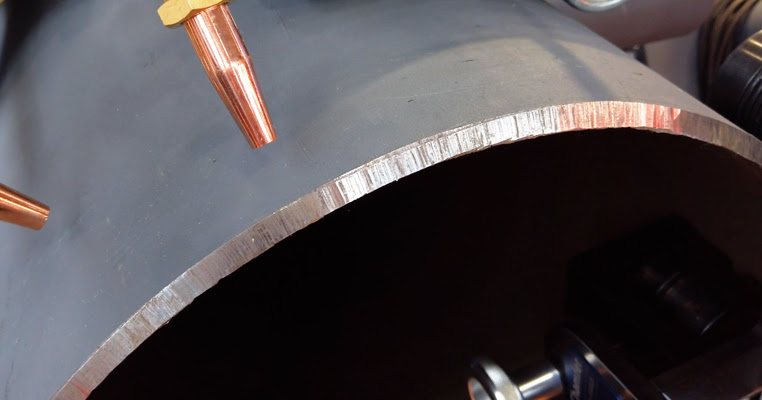

Manual pipe prep can take care of lots of different jobs just fine, and for most shops, it’s all they’ll ever need. But some projects are different – they need a level of accuracy that manual methods just can’t deliver reliably. When you need to hold your bevel angles within 1 or 2 degrees time after time, a rental machine is probably the way to go. With hand grinding, you’re going to see variations of 5 to 10 degrees across the joint, even when experienced workers are doing their absolute best.

The difference shows up in pressure vessels or pharmaceutical systems. These two types of systems need extremely precise and repeatable bevels because the quality standards are very strict. Nuclear piping is in a whole different category – the documentation alone mandates machine preparation for every joint.

The payoff comes through in the weld quality numbers. Fabricators who make the switch to machine-prepped joints usually report their X-ray rejection rates dropping by 40% to 50%. That translates directly into less repair work, fewer delays, and much less frustration all around.

Machine-cut bevels make a welder’s job easier right from the first pass. When the fit-up is uniform and accurate, welders aren’t always battling with poor joint preparation or compensating for bad angles. The root pass lies in cleaner, and there’s way less need for grinding between passes. I’ve seen welders stay more productive throughout their workday when they’re working with well-prepared joints – it’s less physically and mentally taxing.

Some codes explicitly require machine-level precision for particular service conditions. ASME B31.3 and other similar standards are very specific about joint preparation on critical welds – and there’s pretty much no wiggle room for interpretation.

Quality control inspectors can move through machine-beveled joints much faster as well. Because the preparation is so uniform, inspectors spend less time verifying angles and measurements on each joint. This smoother workflow helps projects run on schedule. And depending on the type of material you’re working with, these benefits from exact measurements can become even more valuable to your success.

How Materials Affect Your Pipe Work

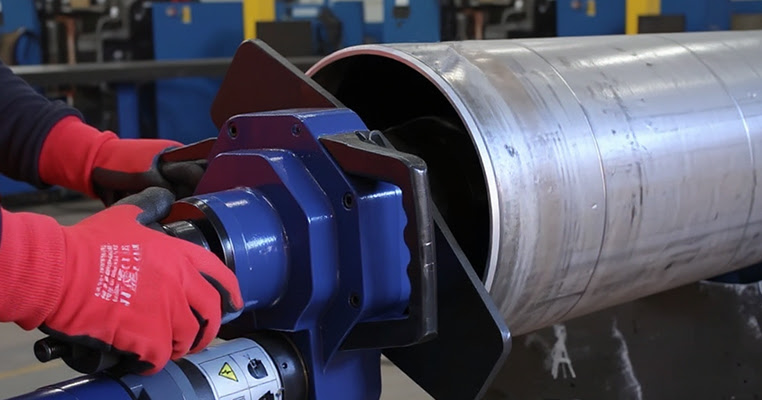

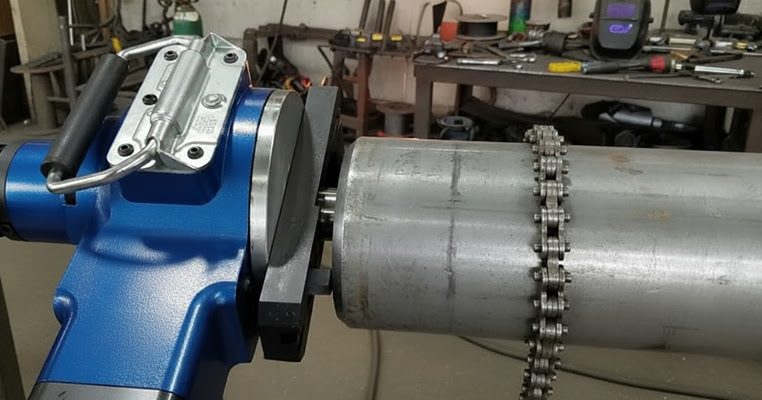

Manual prep work on a large diameter pipe is one job that can test your patience and stamina. A 24″ schedule 80 pipe joint that needs a bevel – if you do it manually, it takes 3-4 hours to grind. A bevel machine will knock out that exact same joint in around 45 minutes. Once you see the numbers like that, it makes you stop and think about which approach makes more sense for your operation.

The type of material you work with has a big effect on whether manual prep is even worth it. Materials like Inconel and duplex stainless steel are especially hard to work with because they actually get harder as you grind them. Each pass with the grinder gets harder than the one before it, and your tools wear down fast. P91 chrome moly is another beast – it presents the same challenges that’ll wear out your equipment and your crew pretty fast.

Wall thickness is another big consideration that shops usually overlook. An operator who grinds thick-wall pipe manually will feel it in their arms after just a few joints. As fatigue sets in, the quality of the work starts to suffer – bevels that were perfect in the morning start to drift off specification by afternoon. When the day ends, the difference in quality between the first joint and the last one can be pretty dramatic. Some materials create safety problems during manual prep work because they release hazardous dust particles into the air. The ventilation systems and the personal protective equipment that you need just to work safely with these materials can be extensive. There are shops where the safety setup takes up half the morning before any prep work even begins.

Special bevel geometries are where manual prep hits its limits. J bevels and compound angles demand a level of accuracy that’s extremely hard to maintain by hand across multiple joints. The wall thickness transitions add yet another variable to the mix, and suddenly, manual prep feels more like a gamble than a process. Small bore pipe under 2″ could be the one area where manual prep still has its place – though even then, if you have hundreds of identical joints to finish, a machine starts to make a lot more sense.

Health Risks for Your Workforce

Manual pipe prep is brutal on the human body, and the damage accumulates way faster than most businesses want to admit. The combination of repetitive motions and awkward positions that workers have to hold for hours causes real damage to their shoulders and backs. Experienced grinders end up out on injury leave for weeks because their bodies just can’t take it anymore. When workers spend 3 or 4 hours on horizontal pipes with a heavy grinder vibrating in their hands, their backs and shoulders end up completely screaming.

The dust exposure is another big concern that’s hard to ignore. Manual prep creates these thick clouds of metal particles that just hang in the air, and even with decent exhaust ventilation running, workers are still breathing in way more dust than they should be throughout their workday. Beveling machines come with built-in collection systems that actually work – they grab most of the particles right at the source before they can float around the workspace. The difference in air quality is really big, and your lungs definitely feel it.

The workers usually come around to preferring machine operation after they’ve had a chance to learn the basics. The controls are simple, and the physical requirements are much lighter compared to manual grinding. Businesses see the benefits in their compensation claims dropping and their crews actually wanting to stay for the next project.

The training time is also a factor that pushes many contractors toward machine rental instead of manual methods. Most beveling machines are simple to learn – operators usually get the hang of it within 4 to 8 hours, and after a full day of hands-on experience, they’re ready to go. Manual beveling takes a completely different level of commitment. You need months of steady practice just to build up the steady hand control and muscle memory for decent results. That time investment turns into a real problem if you have a tight project deadline or need to train temporary workers for a job.

Many union agreements and safety programs have started requiring mechanical beveling for any pipes over certain diameters, and especially in confined spaces where ventilation is already a challenge. Local laws vary quite a bit, so you should verify what applies to your particular project before locking yourself into one method or the other.

Experienced manual grinders are hard to replace when they get hurt. The skillset is so specialized that you can’t simply pull anybody off another crew and expect quality work. Machine operators are much easier to train up in a pinch if somebody needs to step away from the project. I’ve seen plenty of jobs come to a standstill because their best grinder threw out his back. The safety benefits alone usually convince businesses to go with the rental equipment, especially when they’re weighing all their options for a new project.

Where The Pros Get Their Welding Rentals

The choice to rent beveling machines versus manual prep work usually depends on five factors that show up on almost every project. Project volume is the obvious starting point – the amount of pipe you’re actually working with matters. Timeline is next, and it never seems to be quite long enough for what needs to get done. Quality standards change quite a bit from client to client, so that’s another big consideration. Crew safety and productivity round out the list. These two elements have a ripple effect on everything else in the project. Once contractors account for all the less obvious costs and the productivity drop that comes with manual work, the math gets pretty simple.

Pipe work has changed dramatically over the past few years, and these changes have pushed a lot more teams toward mechanical beveling as their primary method. The projects now are far more sophisticated than what we were working on just 5 years ago, and the specifications get tighter and tighter. The deadlines continue to shrink as clients somehow expect even better results in less time. The contractors who deliver exceptional work time after time don’t make the rental-versus-manual choice once and stick with it forever. They take each new project as it comes and go through these same five factors from scratch each time. Manual prep definitely still makes sense in some situations – no question about that. But once you look at what the most modern jobs actually demand from contractors, that rental beveling machine usually turns out to be the better play.

Speaking of having the right tools for the job, this is exactly where Red-D-Arc comes into the picture for welders who need reliable equipment without the massive capital investment. We’ve built our reputation on providing top-quality rental equipment that helps contractors tackle everything from small repair jobs to massive industrial projects.

Whether you decide to rent for a specific project or you’re ready to make a purchase, we’ve got the equipment and the expertise so you can succeed. Head over to Red-D-Arc.com to check out our full range of solutions and see how we can help you hit your project goals while keeping your crew safe and productive.

Leave a Reply