By guest Blogger Katarzyna K.

By guest Blogger Katarzyna K.

Katarzyna has an Msc in Materials Science and has worked in the oil and gas industry in jobs related to hydraulics, welding and the retrofitting of oil rigs.

Stainless steel is used extensively in the petrochemical industry due to its high resistance to severe conditions. When welding inox steels, the smallest details matter and have an impact on weld quality. The following are some tips for stainless steel pipe welding based on my oil rig repair experience:

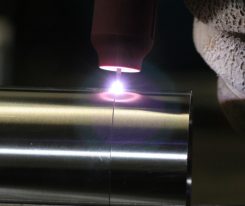

During an oil rig repair project that involved 2205 duplex stainless steel pipe TIG welding, we could not achieve the required weld properties. Despite using the recommended filler metal with higher nickel content, compared to the base metal, and controlling the interpass temperature, the weld tensile strength was still too low. In order to reach the required weld quality we dug deeper and found a solution – pulsed TIG. Welding of stainless steel, especially duplex type, requires control over the heat input. The Miller Dynasty 200 with pulse option was the perfect welder for this situation. Another good practice – adding a small addition of nitrogen (up to 5%) to the argon purge gas. Even with duplex steel welding the maximum amount of oxygen in the purge gas is generally considered circa 2500-5000 ppm O2. In marine or petrochemical applications it is advised to go down as low as 50 ppm O2 in order to achieve high pitting resistance of the joint. The weld tensile strength improved and we continued welding.

Composition

Inox steels contain 10.5% or more chromium which can cause several difficulties during welding. Once the material properties are lost due to oxidation or improper heat treatment, they are difficult to regain, so special precautions should be taken before and during welding. In general, stainless steels require less heat input and therefore less electrical current than carbon steels due to their lower melting point. In order to avoid overheating, welding speed is higher than usual. This may cause problems for welding operators experienced with carbon steel welding in semi-automatic or manual processes. Deformations may appear as stainless steels have greater coefficient of expansion (the material expands more with temperature) than mild steels when heated. Addition of more passes by reduction of bead dimensions is a good idea to reduce the heat input and avoid warping of the material. In pipe welding there is a special pass order recommendation to be followed to avoid deformation.

One should always remember the base rule of not mixing stainless steel and carbon steel elements together. Traces of carbon steel on the stainless steel material may lead to rust formation. This also applies to equipment such as wire brushes, clamps, etc. Special low chloride markers are recommended for stainless steel weld applications.

Tips and Guidelines For Welding Stainless Steel

Stainless steel contains a minimum of 10.5% chromium which imparts it corrosion resistance by forming an oxide layer on the surface. The most common stainless steel is the austenitic type (300 series) which contains chromium and nickel as alloying elements. Other types include ferritic, martensitic and duplex stainless steels. Most stainless steels are considered to have good weldability characteristics. Most common processes used for welding stainless steel are TIG (GTAW) and MIG (GMAW). But, stick welding (SMAW) is also utilized.

Differences in Properties:

The properties of stainless steel differ from mild steel, and these differences need consideration when welding as below:

- Higher coefficient of expansion, 50% more for austenitic – this results in more distortion

- Lower coefficient of heat transfer – welding requires lower heat input as it is conducted away slowly

- Lower electrical conductivity – using the correct and consistent stick-out distance is more critical when using MIG/TIG, higher wire speed for the same current is required when MIG welding

Segregate Your Work Area

Welding of stainless steel is carried out in a work area segregated from carbon steels. Moreover, tools dedicated for use with stainless steel must not be used to work on carbon steels. These tools include brushes, hammers, clamps, grinders etc. The segregation of work area and tools safeguard the contamination from carbon steels, which may cause welding defects and corrosion (rust) on stainless steel. You must also wear gloves when working with stainless steel as this will prevent oil from the hands passed onto the stainless steel.

Preparation is Key!

With stainless steel, it is important that the joint surfaces are thoroughly cleaned before welding to remove any dirt, grease, oil etc. The filler wire also needs to be completely clean.

Additionally, the joint design including the joint gap must cater to the higher expansion rate of stainless steels.

Filler Material Selection:

Filler materials used generally are the same as the base metal. Special considerations are required to select a filler material if welding dissimilar stainless steels or stainless steels where no identical filler material exists. Furthermore, filler materials are selected to reduce the risk of intergranular corrosion and hot cracking.

Welding Considerations For Stainless Steel

It is essential to protect the weld during welding using a mainly inert gas. Additionally, the weld root needs to be purged using a pure inert gas.

When welding austenitic stainless steels, it is important to restrict the heat input to a level which is just sufficient to ensure a good weld. The interpass temperature is limited to 350 F. Preheating is not carried out on austenitic stainless steels. Very low carbon grades (suffixed with L e.g. 304L, 316L) are used to prevent the formation of chromium carbides in the heat affected zones which causes intergranular corrosion.

Martensitic stainless steels are generally used as wear resistant materials in overlaying applications. To avoid cracking, accurate preheat needs to be applied and a minimum interpass temperature maintained.

Ferritic stainless steels are used mostly in automotive applications. The heat input in these steels during welding needs to be limited, and a maximum interpass temperature of 300 F is recommended. This will ensure that the grain growth in the material is controlled and the strength is maintained.

With duplex stainless steels, the heat input also needs to be restricted.

It is also important to keep in mind the dangers inherent in welding stainless steel (like hexvalent chromium) and ensure proper fume removal.

Cleaning and Passivation:

Stainless steel welds must be cleaned and passivated after completion to ensure corrosion resistance and good appearance. This is performed manually by mechanical (brushing, grinding, blasting), chemical (applying pickling agents and other chemicals) or electrochemical means.

Red-D-Arc has a wide range of equipment suitable for stainless steel welding for rent including the following:

Multi process welders capable of stick, TIG, MIG, submerged arc, air carbon arc cutting, flux core, up to 1500 A

Stick welding units – up to 625A

Also 4 and 6 Paks of welders available

Orbital welders – suitable for stainless steel pipe/tube welding

Various brands including Miller, Lincoln, Red-D-Arc

Have a look at our complete range of welding products.

Leave a Reply