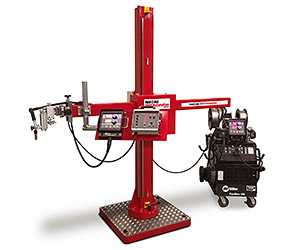

Red-D-Arc has launched an exciting new product designed to increase the productivity and efficiency of pipe welding. The Red-D-Arc Process Pipe Cell with oscillating welding torch is a dual wire feeder, multi-process welding cell.

The system is easy to set up and operate and reduces weld operator errors, reduces welding time, and increases deposition rates, productivity and arc-on time.

A variety of welding power sources and wire feeders can be used with the system including Miller RMD PipeWorx 400 and Lincoln STT S350, S500 and S700 Power Wave systems, with all welding functions controlled via a remote interface.

Root passes can be performed manually with solid wire using either RMD or STT technology (instead of manual GTAW or SMAW) followed up by hot passes and cap passes either solid-wire or flux-cored) with the jammer-style weld oscillator.

Choose the welding positioner, welding chuck, turning roll set or headstock to suit your specific needs. All positioning functions including welding head manipulator, oscillator, welding positioner and turning rolls are managed via a single control.

Contact a Red-D-Arc Weld Automation Expert to learn more or request a demo: 1-866-733-3272 | Contact Sales

See more welding turntables, pipe welders and pipe welding positioners