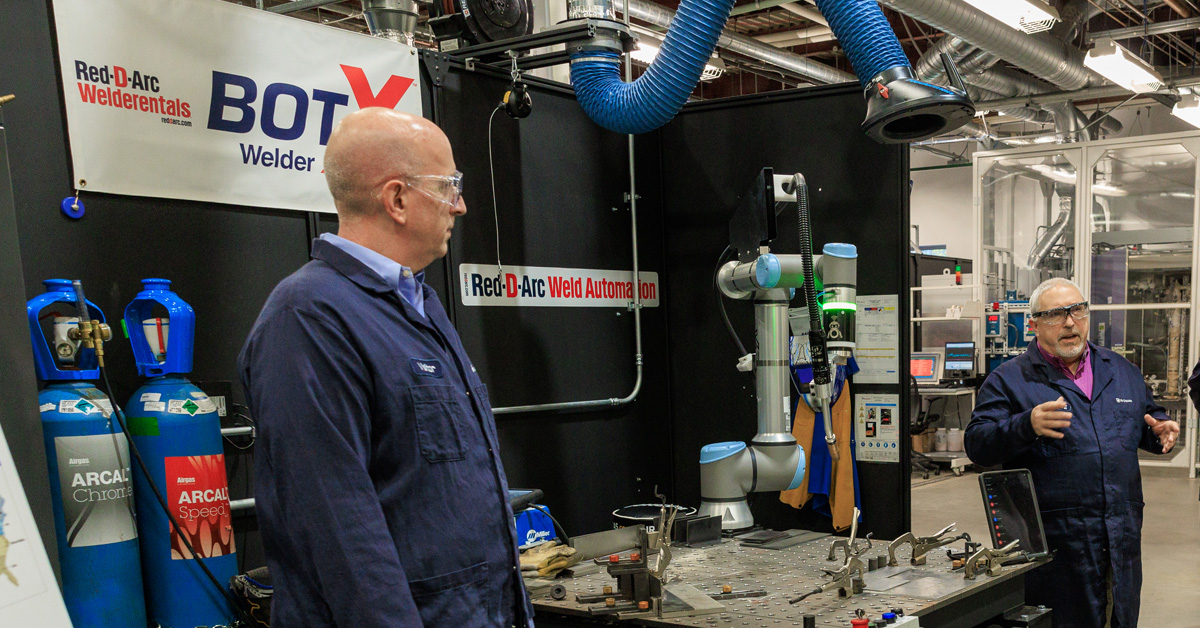

How Do Welding Cobots Give Manufacturers an Edge?

Most of us are aware of industrial welding robots—those large, fast machines found on big assembly lines. But what about collaborative robots, also known as cobots? These compact machines can work safely alongside humans, but don’t let their size fool you; they’re the next big thing in welding automation.

Let’s explore how Red-D-Arc’s welding cobot can support your operation.

Setup is a breeze

If you can operate a smartphone, you can set up and operate the BotX welding cobot. Traditional industrial robots can take weeks to install and program. This same app offers a real-time cloud connection, which allows for 24/7 performance monitoring and troubleshooting support.

Red-D-Arc provides users with the opportunity to configure their equipment quickly and easily through a mobile app. This same app offers a real-time cloud connection, which allows for 24/7 performance monitoring and troubleshooting support.

Costs effective, flexible acquisition options

Cobots offer a low-cost, flexible alternative to traditional robots. Red-D-Arc’s BotX welding cobot can be rented by the week, or purchased, allowing customers to scale up or down quickly on an as-needed basis. In comparison, large industrial robots are usually purchased as long-term capital investments.

The cost of a cobot depends on more than just its size. Technological advances within the cobot space are bringing this technology within reach for small and medium-sized manufacturers, enabling them to compete with their larger rivals.

Safety first

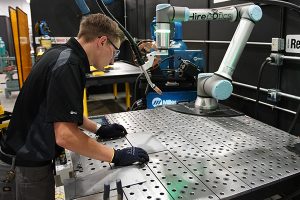

Does your process include tasks that are dirty, dull, or dangerous? Then a cobot might be just what you need. The key is in the robot’s full name— The BotX collaborative welding robot.

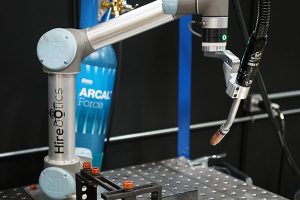

The BotX cobot supports humans; it doesn’t replace them. And its design allows it to safely work with people in the same cell or work envelope. ISO/TS 15066:2016 ensures that all welding cobots meet strict safety standards without the need for cages and other physical barriers, which can reduce the risk of musculoskeletal injuries by taking on repetitive tasks that would otherwise be performed by human welders.

Flexibility = productivity

Industrial welding robots are typically bolted to the floor and used for one main purpose for years at a time. The BotX, on the other hand, is small enough that it can be moved around to support different welding jobs within a plant.

The BotX is perfect for enterprises that thrive on high-variety, low-volume work. With various available configurations, companies can adapt the BotX to meet a variety of welding needs and challenges. In addition to helping with repetitive tasks, the BotX can also support operations that require accuracy and repeatability.

Summary

Gone are the days when welding cobots were just for large assembly lines. With the innovation of the BotX collaborative welding robot, more small and medium-sized businesses can explore automation without the need for costly investments and special expertise

To learn more about how the BotX welding cobot can help solve your shortage of skilled welders. Contact your local Red-D-Arc representative today at 1-866-733-3272 or fill out the contact form at reddarc.com/botx to get your questions answered about the BotX