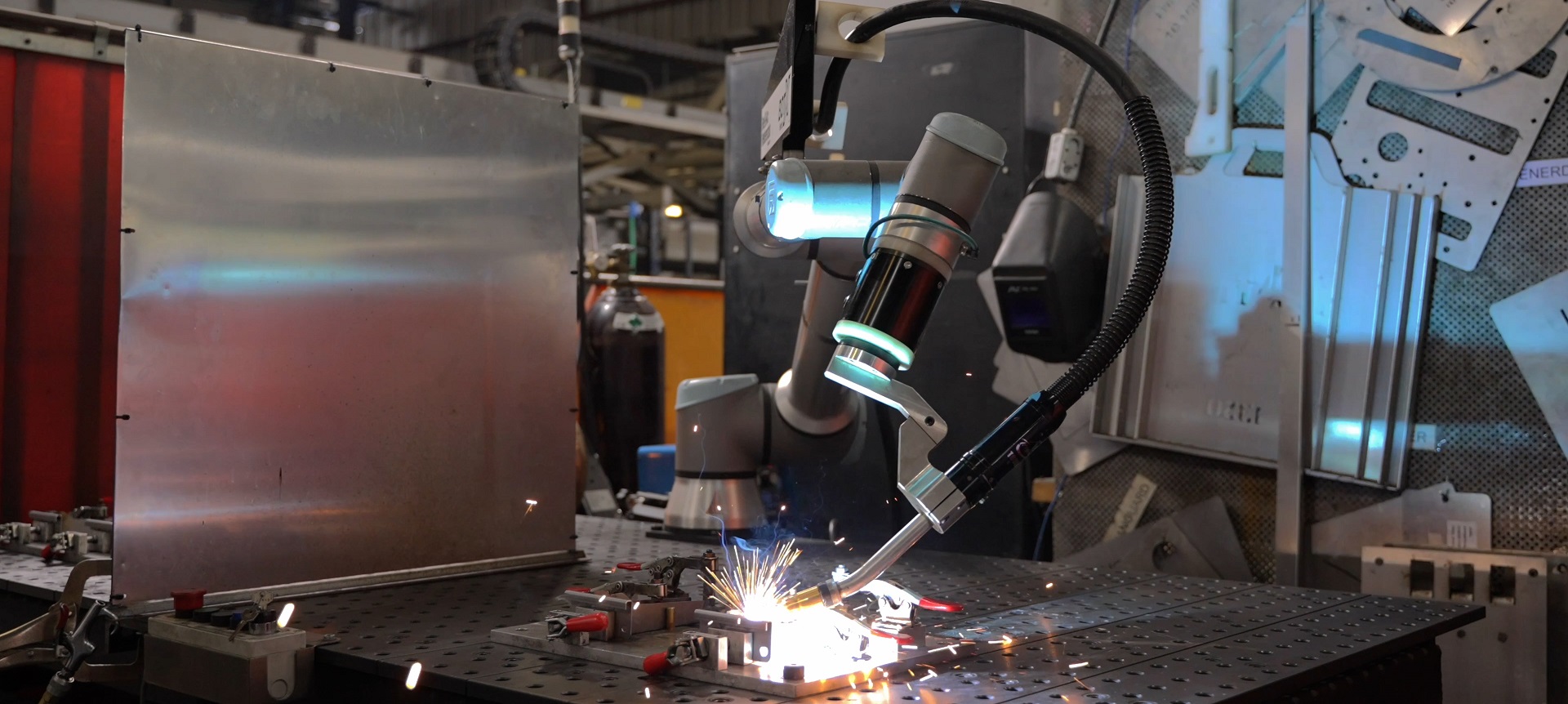

Could the BotX™ cobot welding system help solve some of the challenges you’ve been facing? It did just that for Estes Design and Manufacturing, a full-service sheet metal fabricator in Indianapolis, IN. Hear from the company’s Laser Welding Supervisor, Casey Gaudin, who spoke with us about some of the results that they’ve achieved since implementing BotX into their production. Casey told us that Estes has experienced a significant increase in speed, enhanced repeatability of parts, and a notable decrease in rework. In fact, with one part that they transferred from manual welding to the cobot, there was an improvement of 120% in cycle time.

Finding the right people with the right skills was another challenge that Estes was facing so it was critical for them to have an automation solution that was easy-to-use. Fortunately, they’ve found that the BotX system is fairly simple to run and very user-friendly. Casey remarked that they’ve been really impressed and have been able to take operators and get them programming parts and running the machine in as little as 15 minutes. We’re proud to say that BotX has been a success for Estes Design and Manufacturing, and when asked about his experience with BotX, Casey summed it up by saying, “If you’re wondering about getting a BotX or not, I would highly recommend it. If your company has large volumes of parts and is having trouble finding qualified welders, then the BotX is for you.”

Watch the video to hear their story and see how BotX has added more efficiency to their operations.

For more information about the BotX cobot welding system and to connect with an expert, visit BotXWelder.com.